views

Completing Educational Requirements

Complete high school or earn your GED. While you’re in high school, speak with a counselor or high school advisor to find classes that will best prepare you for working with sheet metal. Take math and technical classes if they are available to you. Graduating from a high school study program will open up more opportunities when you begin searching for jobs. The GED is considered to be the equivalent of a high school education. If you don’t finish high school, take the GED test instead. Some metalworking companies work with high schools to create training programs. If you happen to have one of these programs in your area, take advantage of it to get started on your training while you’re still in school.

Study algebra and geometry to prepare for the math involved. Sheet metal workers deal with a lot of measurements. Expect to have to measure sheet metal and calculate angles before cutting it to size. Brush up on your measurement and calculation skills through any algebra classes available at your school. To learn how to work with angles, take geometry or even trigonometry. Precision is important for a sheet metal worker. For example, you may be asked to make a heating duct that covers a specific amount of wall space. If it isn’t the right shape, it may not fit or work correctly.

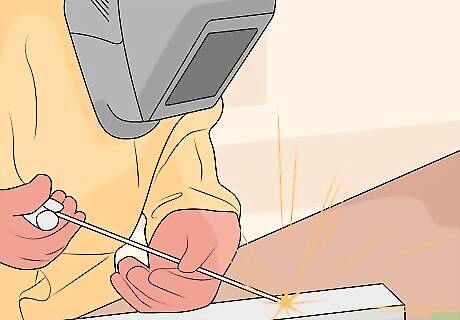

Practice technical skills through available vocational courses. Many high schools have vocational programs that can prepare you for life as a sheet metal worker. If they are available, take classes covering topics like how to read and draw blueprints. Welding is another crucial skill that vocational programs often teach. Get accustomed to the tools commonly used on the job. Some common ones include metal shears, plasma cutters, hole punches, presses, and crimping machines.

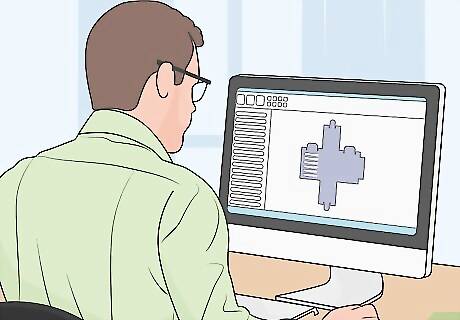

Practice operating design programs on a computer. Companies design projects through programs on the computer. If you’re comfortable using a computer, you will have an advantage once you start applying for jobs. Check out computer-aided design (CAD) programs like AutoCAD, for example. There are free CAD programs you can download and use at home. As a sheet metal worker, you may be asked to read a CAD blueprint and refine sheet metal to match it. You may even be asked to create projects using CAD software! Construction companies also use building information modeling (BIM) software. These programs

Gaining Additional Training

Complete a 4 to 5-year apprenticeship as a sheet metal worker. Most sheet metal workers learn the trade by becoming an apprenticeship. After leaving high school, apply with sheet metal workshops and factories that have apprenticeship programs. They provide paid on-the-job training and educational classes. Companies often hire their apprentices full-time after finishing training. To become eligible for an apprenticeship, you have to be 18 years old with a high school diploma or GED. Most future sheet metal workers start their apprenticeship right after high school. Note that landing an apprenticeship can be a difficult and competitive process. If you don’t get in right away, keep trying.

Go to technical school if you need additional training. If you’re unable to find an apprenticeship right away, technical school may be right for you. Search for schools near you that have programs for protective sheet metal workers. Some of them don’t have specific programs, but you can take courses like sheet metal fabrication and welding to prepare. This can be a useful option if you didn’t receive technical training in high school. If you attended a vocational program in high school, you most likely have the basics down. Technical school is the best option for people that don’t have much formal experience with sheet metal.

Work as a helper in a company if you can’t find an apprenticeship. It may not be the role you want, but it can be a stepping stone to becoming a full-fledged sheet metal worker. Helpers do small tasks around workshops and factories. They serve as assistants to other workers, such as preparing tools, moving material, and cleaning up. Start out as a helper, then advance to sheet metal work as you gain experience. Consider a helper role to be a way to gain experience in a factory setting. Companies often offer apprenticeships or training opportunities to dedicated employees taking the initiative to improve their skills. If you’re working as a helper, take classes at a nearby technical school as well. It will increase your chances of getting promoted to metalworking.

Advancing Your Career

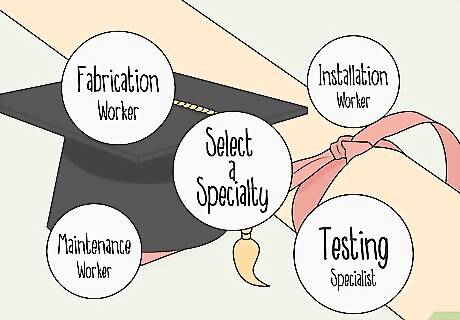

Select a specialty depending on what you want to make. Sheet metal work can be divided up into 4 specialties. Fabrication workers are the most common and make household products in a factory. Installation workers install those products and often work on construction sites. Maintenance workers are responsible for fixing up old or worn-out products. Testing specialists make sure products are working correctly and often double as installation and maintenance specialists. If you prefer working in a factory, for instance, fabrication is the best choice. If you don’t mind doing things like installing ducts in new buildings, then installation or maintenance may be right for you. Although most specialists work in factories, some of them work outdoors and may need to deal with the tough conditions of a construction site. Search for different apprenticeships and jobs depending on what you want to do. If you intend on doing installation work, look for opportunities with construction or heating and cooling companies, for instance.

Get professional certifications related to your work. Sheet metal workers generally don’t have to get a license, but certifications can open up new job opportunities. For example, some people earn a certification for precision sheet metal work. Also, look into welding, BIM, testing and balancing, and similar duties. These certifications are given out by professional organizations and you can apply for them online. For example, check out The Fabricators & Manufacturer’s Association for precision work certificates. If you’re in the U.S., apply to the American Welding Society for welding certificates. Certification rules may vary depending on where you live. For more information, consult government regulations.

Master welding and additional skills that will help you succeed on the job. Welding is a very important part of sheet metal work, so it is often taught in beginning vocational and technical programs. However, there are many different welding tools and techniques, so you can always find something new to learn and get certified in. Another option is to learn more about operating CAD or BIM programs on the computer. If you have good communication skills, you may also be able to ascend to a project management position and direct a team of sheet metal workers. Practice your computer skills to gain experience designing projects through CAD and BIM programs.

Comments

0 comment