views

Make sure you have a clean, well lit work area and the proper tools before you begin. These devices have small fasteners and parts which must be kept clean and safe while you work on them, and some have special fasteners that are difficult to remove without the right tools.

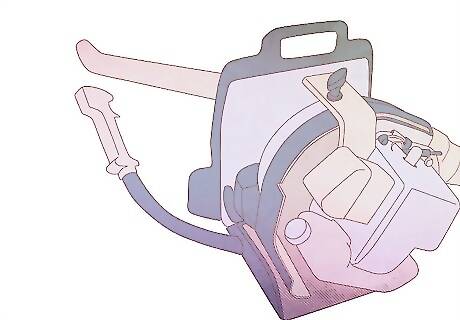

Brush or use compressed air to clean the outside of the engine and the air cleaner housing before beginning. This will make it easier to keep the internal parts of the carburetor clean while disassembling it.

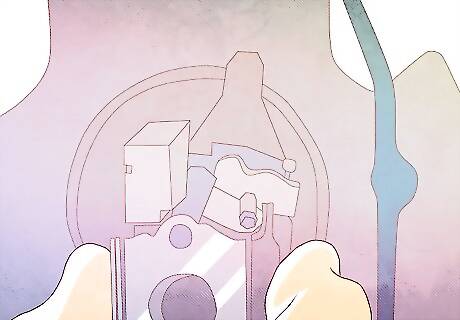

Remove the air cleaner housing. It may be attached with clips or screws, you should be able to locate them by inspecting the housing visually. If you cannot remove the housing on the engine you are working on, consult the owner's manual or search specific information online.

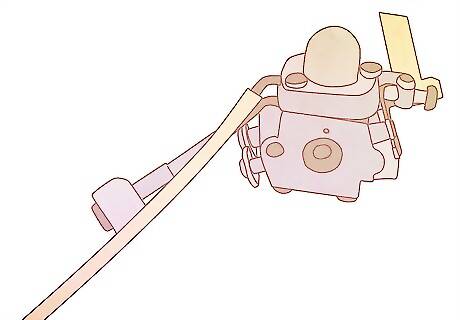

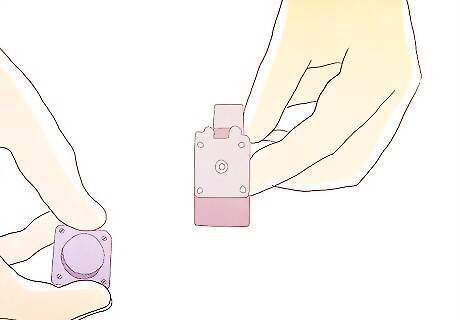

Remove the fasteners that hold the carburetor onto the engine. There are usually two threaded studs with nuts and washers that serve this purpose. Be careful not to drop these nuts in an inaccessible location beneath the powerhead.

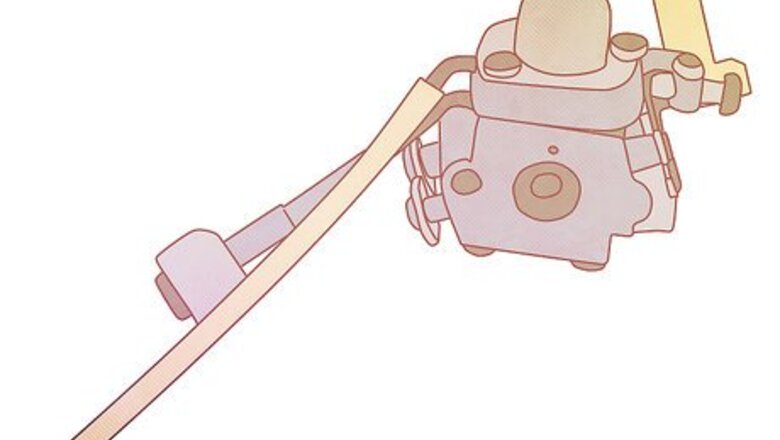

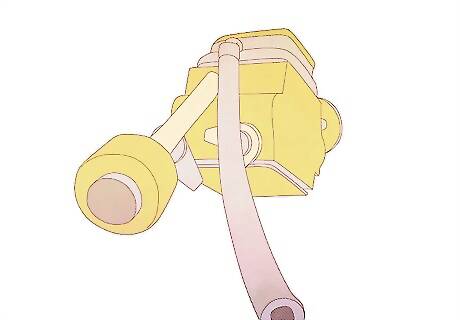

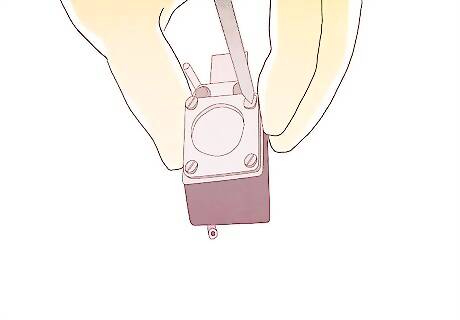

Disconnect the throttle and choke linkages from the carburetor, noting how they fasten and where each one is attached. If there is a spring clamp, be sure that you do not overstretch it while removing it.

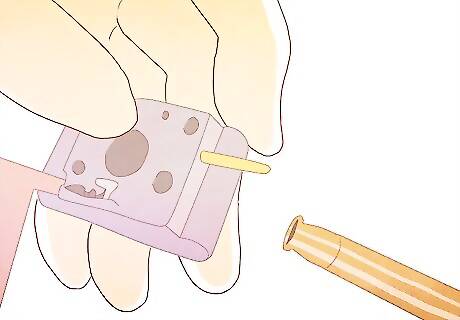

Remove the fuel lines from the nipples connecting them to the carburetor housing. You can usually grip them gently with needle nose pliers and work them free. If clamps are used to attach them, remove the clamps prior to trying to remove the fuel lines.

Pull the carburetor off of the mounting studs, being careful not to damage the gasket that seals the carburetor throat to the engine. Again, note the position of the carburetor, most are symmetrical, so they can be reinstalled upside down, and the aforementioned linkages and fuel lines will not fit if that is the case.

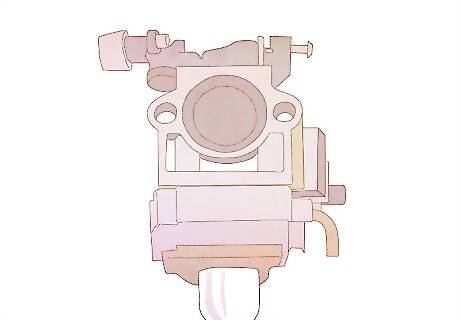

Blow off any dirt or other debris from the outside of the carburetor, being careful not to allow it into the throttle body in the process. Brush any stubborn dirt off with a soft bristle parts brush, using a solvent like carburetor/choke cleaner or unchlorinated brake cleaning solvent to make the job easier.

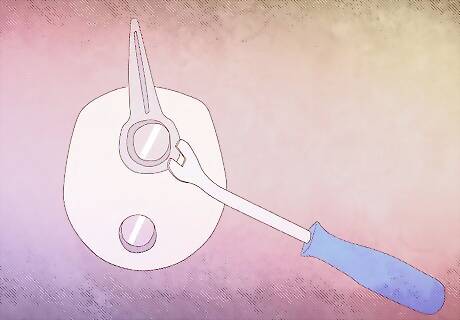

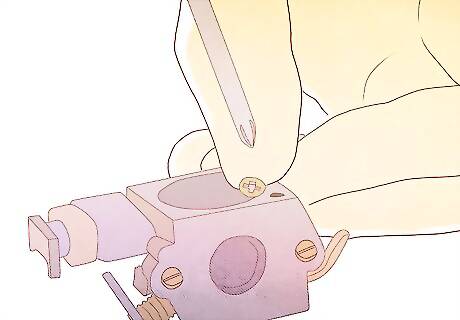

Remove the screw from the diaphragm cover plate and pry the cover off, while being careful not to deform the metal housing or damaging the gasket. You can now ease the edge of the diaphragm up a little to look for dirt or debris underneath it in the fuel channels and the small reservoir. If debris is visible, use canned compressed air to blow it out. Use solvent to dissolve any gum or varnish present only if needed.

Reinstall the cover plate when you are satisfied the area underneath the diaphragm is clear. For carburetors that have a large, visible buildup of varnish or gum underneath the diaphragm, you may have to remove it completely, but in this case, you will probably need to buy a rebuild kit with new parts, as damage to the diaphragm is likely to occur while removing it.

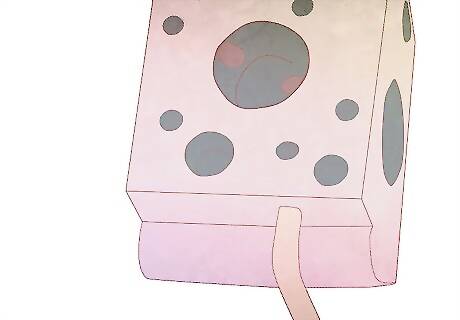

Remove the carburetor base to access the internal screen (fuel filter). Again, remove the four screws (usually), and pry the cover gently off of the carburetor. If you damage the gasket, you will need to purchase a replacement, so be careful.

Look into the larger hole near where the main fuel supply line connects to the carburetor. If you see varnish buildup or trash in the screen, use a solvent (carburetor/choke cleaner) to dissolve it. For heavy buildup, you may need to fill a small, clean solvent proof container with solvent and soak the complete assembly for a short time to dissolve it.

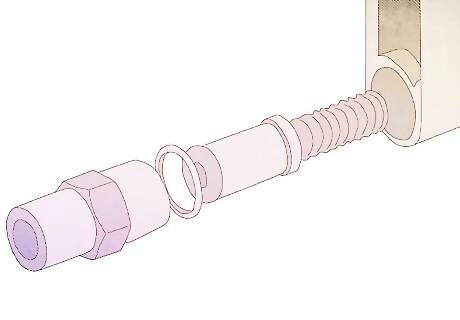

Use a tube applicator on your aerosol can of solvent to blow out the ports the the carburetor housing. You can also spray solvent through the tubes where the fuel lines connect to the housing.

Blow out the excess solvent and any remaining debris from the carburetor housing and ports with compressed air, then inspect the whole assembly to make sure it is spotlessly clean.

Reassemble the cover, making sure all of the screws are tightened snugly.

Reinstall the carburetor by reversing the removal steps found earlier in the article.

Test run the engine.

Comments

0 comment