views

Preparing a Lock for Picking

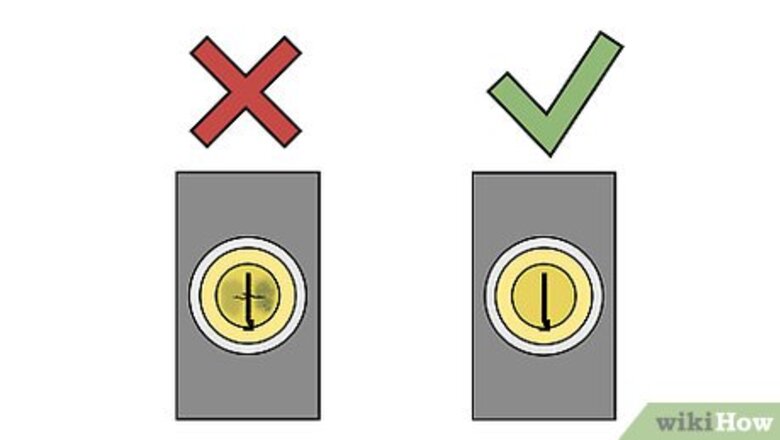

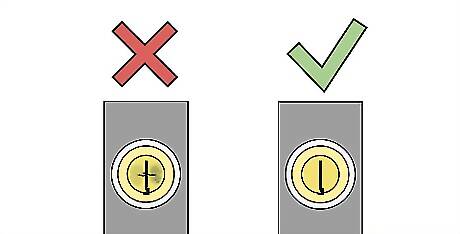

Check the condition of the lock. You won't be able to pick a lock if it's broken. Rusted locks may be frozen shut no matter how skillful your lock picking technique is. Investigate the overall condition of a lock before attempting to pick it. Rusty locks may be restored to pickable condition with the application of a suitable lubricant, like WD40.

Gather your lock picking supplies. A professional lock picking kit will contain tools like tension wrenches, picks, and raking tools. You'll also need a suitable lock lubricant, like lubricating graphite, which should be available at your local hardware store. You can use household items as substitutes for picking tools, like a bobby pin or a paperclip. You may need to go to a specialty store, like a spy store or a locksmith, or an online seller to buy a lock picking set. Although owning a lock picking set is legal in most regions, if caught by police with these tools on you, there may be laws that require you to prove you weren't intending on committing a crime.

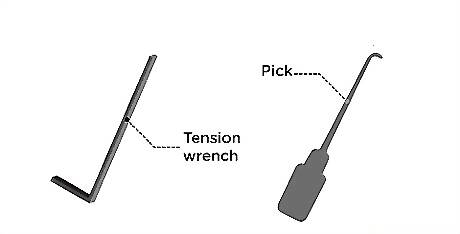

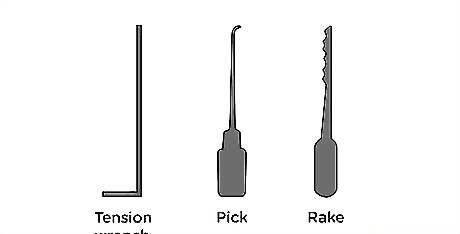

Identify the uses of the three main tools in lock picking. Knowing the uses and names of basic lock picking tools will make it easier to talk about them. This is especially important because pop culture has misrepresented some tools. The three main tools include: A tension wrench. Also called a torque wrench, this tool is a thin piece of metal with flared ends. It is L-shaped or Z-shaped, where the diagonal line of the Z is straight. It is inserted into the plug (the part of the lock that turns) to apply pressure to it. A lock pick. These generally have a handle that narrows to a thin, pointed piece of metal that curves slightly at its end. The pick manipulates the inner parts (pins) of the lock mechanism. A rake. These are picks with many ridges. Some rakes may have a triangular point on the end or be rounded. These are scraped across the inside of the lock mechanism (pins) to disengage it.

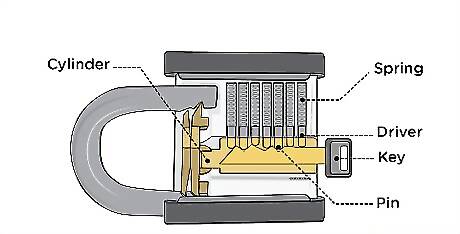

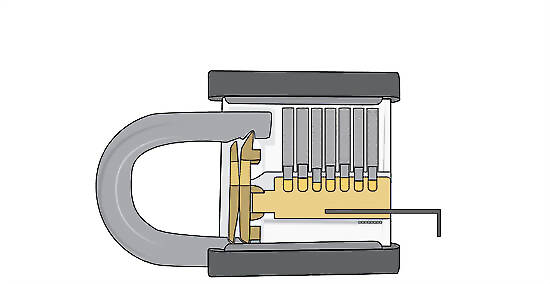

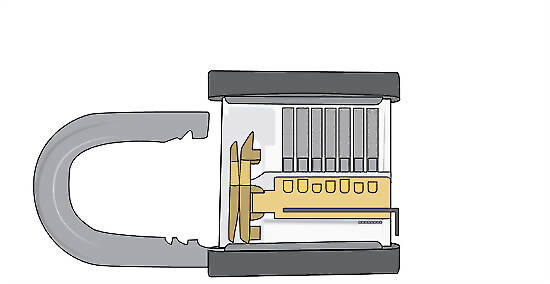

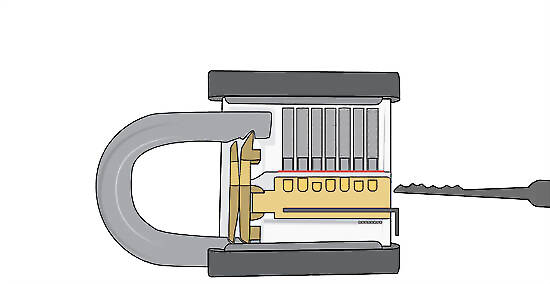

Envision the lock mechanism. When a key is inserted into the keyway of the plug (the turning part of the lock), the wards (ridges/teeth) of the key push up spring-loaded pins. Each individual lock pin is actually made up of a set: a key pin and driver pin. When the break between each set of key and driver pins aligns with the lock turning mechanism, also called the shearline, the lock turns and opens. You won't be able to see inside the lock when picking it, so having a firm mental image of the mechanism is vital. The number of pins varies from lock to lock. Padlocks often have 3 or 4, while door locks generally have 5 to 8. Some locks, especially those in Europe, are situated with the pins at the bottom of the keyway instead of the top.

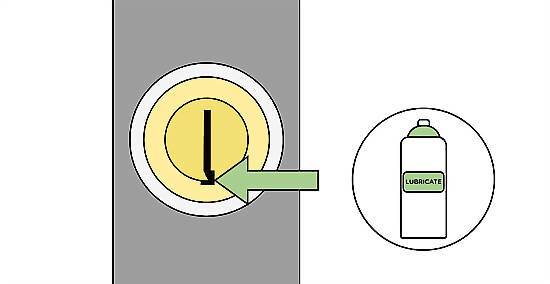

Lubricate the lock. Pins in the lock may be frozen from lack of use. Dirtiness can make the lock mechanism difficult to manipulate. Resolve these problems and give yourself the best chance of picking the lock by applying lock lubricant to it. Many kinds of lock lubricant have simple spray applicators that allow you to direct lubricant into the keyway.

Solving a Common Tumbler Lock

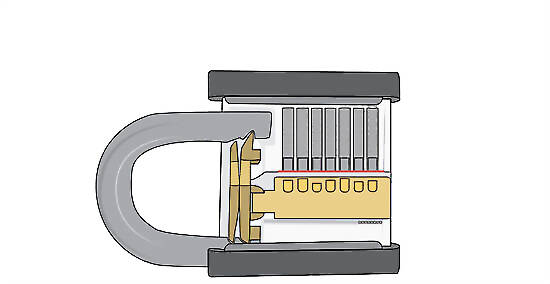

Note the main goals of the lock picking process. While applying light pressure with your tension wrench to the keyway, you're going to push up pins inside the keyway with your pick, one by one. When a pin is lifted enough, the tension from the wrench will prevent it from falling and the next pin can be set. When all pins are set, the lock will open.

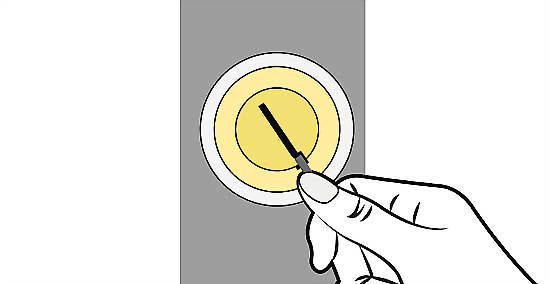

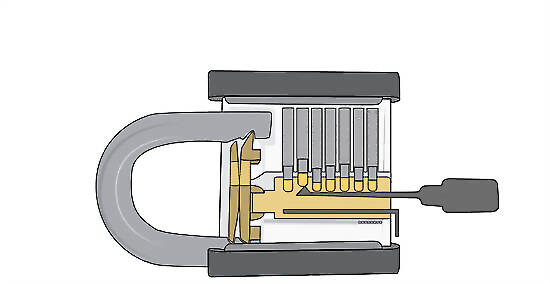

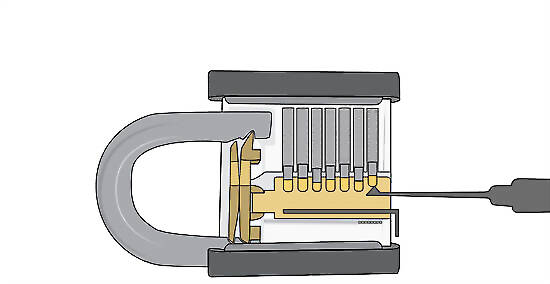

Determine the direction the key turns. Insert your tension wrench into the top or bottom of the keyway. Gently turn the wrench to apply torque (tension) to the plug. The plug will turn one way a little more than the other. This is the direction the key turns. It's easy to apply too much force to tension wrenches. While getting the feel for picking locks, you may want to only use a single finger to apply tension to the wrench.

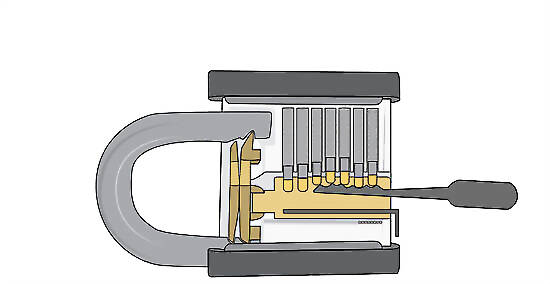

Investigate the pins with your pick. Insert your pick into the keyway. Gently feel the outline of the pins using your pick. Single out one that is accessible. Apply light but slowly increasing pressure to the pick until you feel the springs of the pin give way. Remove the pick. Try to hold the image of the pins in your mind. Doing so can help you keep track of solved pin positions should you have to reset the lock and begin picking afresh. By applying increasing pressure to a single pin, you can test the resistance of the pin springs. Some may be stiffer than others and require more pressure. Generally, the inner workings of locks are relatively delicate. Always err on the side of too little force to prevent accidental lock or pick breaking.

Apply gentle pressure to the keyway with a tension wrench. Insert your tension wrench into the bottom or top of the keyway. Turn the wrench with gentle pressure. Feel how the plug shifts. Release pressure on the wrench. Repeat this process a few times. Your goal, at this point, is to get a sense of the tightness of the plug and to feel for the position where the pins bind in the lock mechanism, freezing it and stopping the plug from turning.

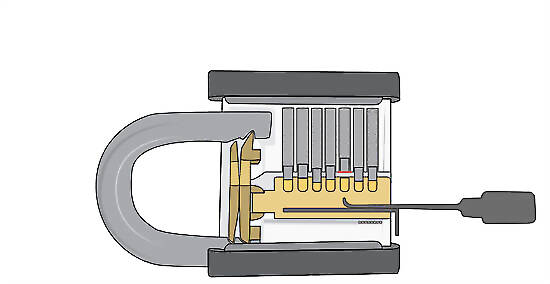

Identify the binding pin. Apply gentle pressure to the plug again with your tension wrench. Insert a pick into the keyway. Lightly touch the pins with your pick as you apply tension. Release tension on your wrench. Continue this process until you identify one pin that binds (resists) more than others when light tension is applied. This is the first binding pin. When you identify the binding pin, maintain steady pressure on your tension wrench. Too much pressure will cause the lock to freeze, too little and the pins will reset.

Set pins one at a time with your pick. While maintaining consistent pressure with your tension wrench, lift the first binding pin with your pick little by little. Eventually, your tension wrench should turn the plug very slightly. The first pin should now be set in place. Use your pick to find the next pin that binds more than the remaining ones and similarly lift and set it. Repeat this until all pins are set. In many common locks, pins will set either front-to-back or back-to-front. However, keep in mind that this is not always the case. Lifting a pin slowly will allow it to set more easily. With practice this motion can become significantly more rapid, especially when paired with the later described raking technique. Applying too much torque to your tension wrench at any point could cause the lock to freeze. In this case, you'll likely have to relieve pressure on the wrench to reset the pins and start again.

Open the lock. When the last pin sets, the lock should fully disengage and open. You may have to apply more pressure with your tension wrench to turn the lock open. A little extra force can be applied with the pick if it's still inserted in the keyway, though you should take care not to jostle any pins or damage the pick.

Using the Raking Technique

Feel out the lock with your tension wrench and pick. Much as you would normally, get a feel for the plug with your tension wrench. Insert your pick into the keyway and lightly feel the position of pins. Press a single pin to test pin spring stiffness. Though the raking technique is generally faster for knowledgeable lock pickers, it operates on the principles of picking a single pin at a time, and will be easiest for those with some experience picking pins one by one.

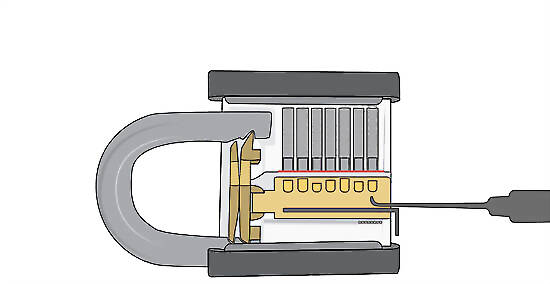

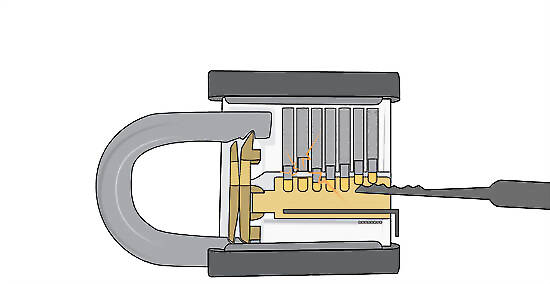

Rake the pins with a rake-tool. A normal pick or a rake can be used to perform this maneuver. Apply light, steady pressure to the plug with your tension wrench. Insert your rake-tool into the keyway slowly and smoothly. Draw the tool upwards and out of the keyway in a snap. When drawing your rake-tool out of the keyway, the pressure applied by the tool should be on its tip only. Your pick should be long enough so that it comes in contact with every pin in the lock while raking.

Listen for pins falling. Raking usually takes multiple attempts before it is successful. After raking, listen carefully to the lock when relieving pressure on your tension wrench. The sound of pins falling indicates you're using the correct pressure with your tension wrench.

Draw your rake-tool back and forth along unset pins. Rake the pins as described previously. While keeping pressure consistent with your tension wrench, use the tip of the tool to "scrub" unset pins. If the pins refuse to set, release pressure with your wrench and start again. Continue until the lock disengages and opens. When most of the pins are set, you may need to increase the pressure on your tension wrench and lightly intensify scrubbing.

Comments

0 comment