views

Prepping Your Work Area

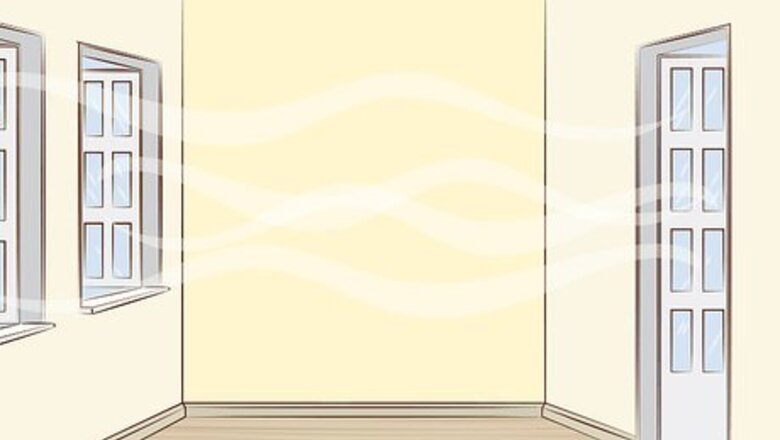

Create cross-ventilation. Generally, you need chemicals to remove polyurethane. Because these chemicals are often harsh, you need good ventilation to protect yourself. If you can, go outside to work. If you're working on floors, create cross-ventilation to help keep you safer. To create cross-ventilation, open the doors and windows in the room. Also, it's a good idea to set up one fan blowing inward and one fan blowing towards the outside to get the air moving.

Protect the floor. If you're working on a piece of furniture inside, you should put something down to shield the floor from drips. A plastic tarp underneath the piece of furniture should work well to provide protection. You can tape down the edges if you're worried about tripping.

Protect yourself. Paint stripper can do a number on you if you're not careful. You'll need rubber gloves to protect your hands. Wear goggles to protect your eyes. Finally, you'll need a vapor ventilator mask, also known as a respirator, available at hardware stores, so you don't inhale the fumes. You should also wear closed-toed shoes, long sleeves, and pants if possible.

Choose your paint stripper. Chemical-based paint strippers, such as those with methylene chloride, are very effective. However, they're also more harsh on your skin and can cause respiratory problems if you're not careful. If you're worried about the effects, you can use water-based strippers instead, though they do take much longer to work.

Applying the Paint Stripper

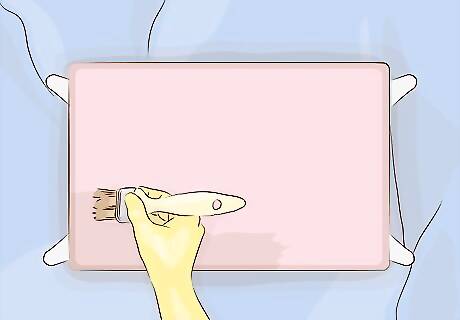

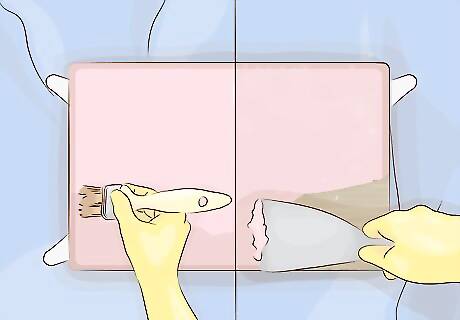

Paint a liberal coating of stripper on the area. Completely coat the polyurethane with paint stripper. It needs to look wet with the paint stripper, so be generous with your application. Use an old paintbrush or even a paint roller. Be sure to get into any nooks and crannies. The type of paint brush isn't important, but you may want to get one you'd be willing to throw away afterwards.

Let it soak in. The paint stripper is going to do the work for you, so you need to let it soak into the polyurethane. Ten minutes is usually enough for a chemical-based paint stripper. You'll know it's ready when the polyurethane starts wrinkling and bubbling. If you're using a water-based stripper, it will take much longer to work, maybe even six to twenty-four hours. Check the back of the can to find out how long it should take.

Cover the project if you need to take a break. If you need to leave the project for longer than it says on the back of the can, then you should try to cover the project to keep the paint stripper wet. The stripper needs to be wet to soak in properly. Another plastic tarp should be sufficient, and you can place it lightly over the furniture or flooring.

Scrubbing off Polyurethane

Use a scraper to scrub it down. A metal scraper is a good place to start, though if you're worried about scratching the surface, you can use a plastic one. The polyurethane should peel off fairly easily as you move along. The paint stripper should have done the hard work. Scrape in the direction of the wood grain. Scrubbing against the grain can damage the surface of the floors or furniture. Plus, if you add any scratches, it will look like the grain of the wood.

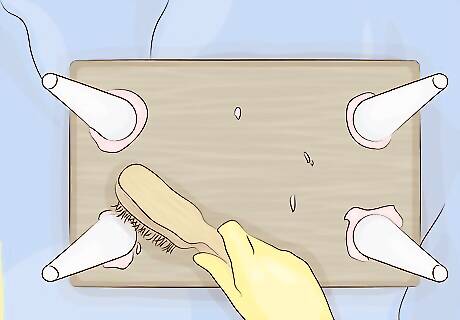

Use a steel brush to get into small areas. In curved or decorative areas, a scraper won't work as well. Instead, scrub it with a metal brush, as the bristles will get in all the nooks and crannies and remove the polyurethane.

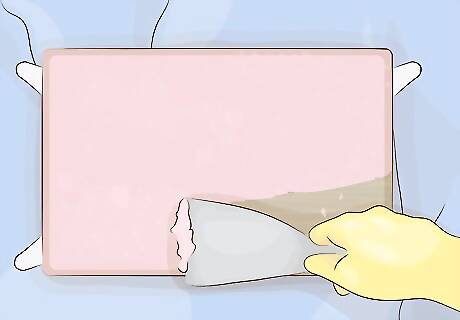

Rub the polyurethane down with after wash. After wash is a solvent you use after paint stripper. Its purpose is to clean up the end of the polyurethane, as well as remove the paint stripper you used. Just use a paper towel to rub it in. You don't have to leave it on for any time. Just rub it on until the rest of the polyurethane comes up.

Repeat as needed. If the first round didn't take off enough of the polyurethane, go through the process again. Apply another layer of paint stripper to the area, and then scrape it down again, checking to see if that completed the process.

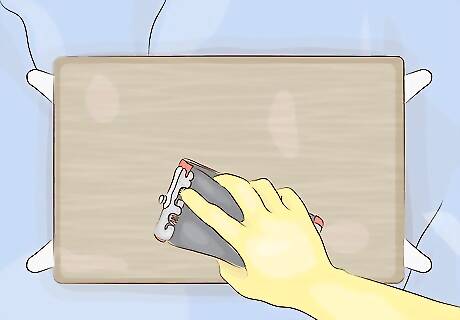

Sand the surface to remove polyurethane. After you've removed most of the polyurethane, sand down what remains. You can simply use fine steel wool. You can also use 150-grit sandpaper. The sandpaper will smooth it out and take off the last of the polyurethane. The after wash should have taken off most of the polyurethane, which is why you shouldn't need a heavy-duty sandpaper. Always rub with the grain.

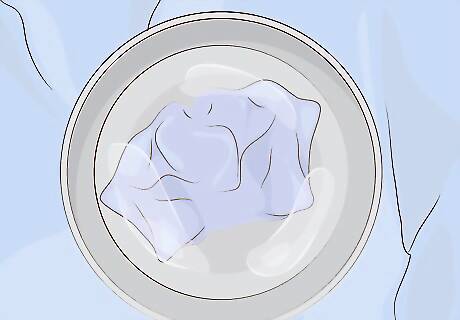

Soak your discarded rags and steel wool in water to avoid fires. Take the water and rags to a hazardous waste disposal unit in your town, along with leftover stripper. Do not throw rags and chemicals directly into the trash or sewer. Contact your city to find your local waste disposal center.

Comments

0 comment