views

Winding the Bobbin

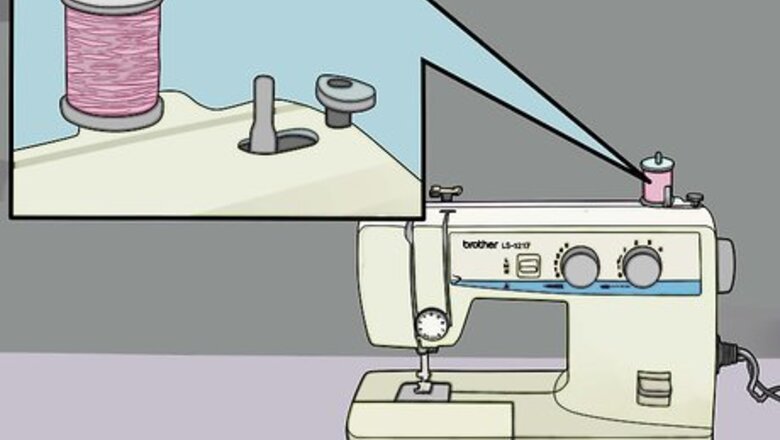

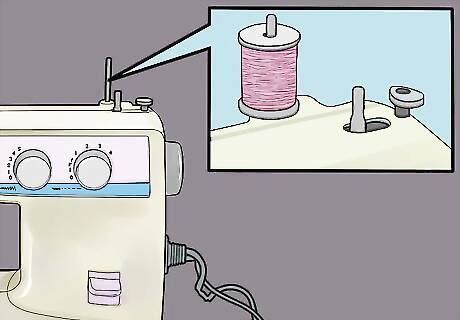

Position the spool. Sit the spool of thread on the spool pin at the top of your machine. Note that the sewing machine must be turned on when you wind the bobbin. If you are using a previously wound bobbin, you can skip this section and consult only the "Threading the Needle" and "Loading and Drawing Up the Bobbin Thread" sections.

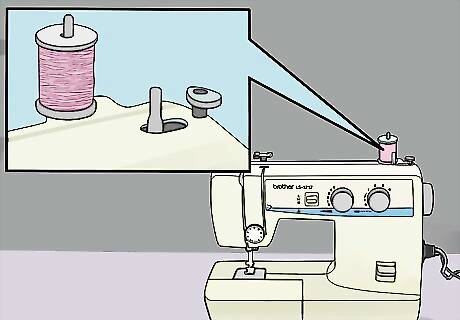

Wrap the thread. Draw the tail of thread from the spool across the top of the machine and around the bobbin winding tension disc on the opposite side. Make sure that the spool rotates in a clockwise direction as you unravel the thread. If it doesn't, you may need to change the way it sits on the spool pin, Wrap the thread around the front of the disc first. It should pass over the left side of the disc, then cross back over toward the front of the machine.

Draw the thread into the bobbin hole. Bring the end of the thread tail up through the hole in the bobbin. The thread should pass through the hole starting from the inside and moving out through the top. Draw at least 2 to 3 inches (5 to 7.6 cm) of thread through this hole.

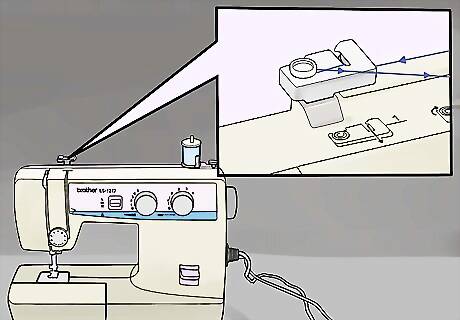

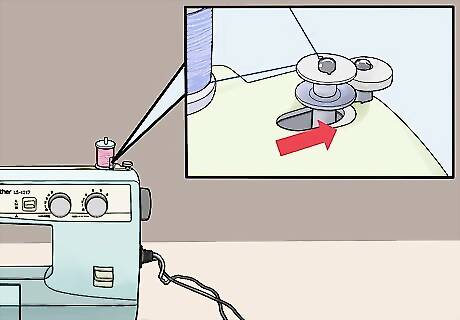

Lock the bobbin in. Place the bobbin on the bobbin winding shaft and slide the shaft to the right to lock it in place. Make sure that the tail of thread and its corresponding hole face up. Carefully turn the bobbin clockwise by hand until you see the spring on the shaft slide into the slit of the bobbin, thereby securing it.

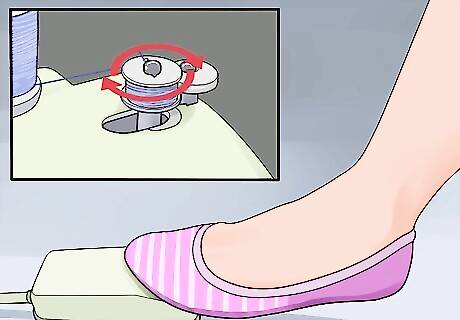

Wrap the thread around the bobbin. Hold the tail of the thread and lightly press on the foot controller. Allow the thread to wrap around the bobbin several times, then remove your foot from the controller. Once the bobbin has been started, trim the tail of thread sticking out from the top of the bobbin.

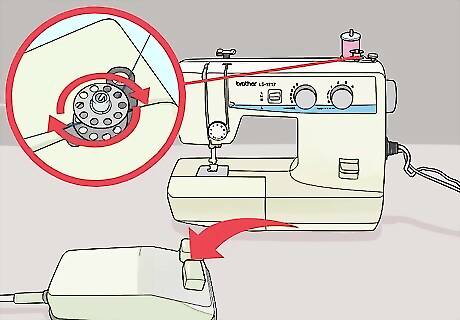

Wind until the bobbin is full. Press the foot controller again and allow the bobbin to wind more rapidly. Continue winding until the bobbin is full. Note that the machine should stop automatically once the bobbin is full. The balance wheel will continue to turn while the bobbin is being wound, but you should not touch it since doing so could damage the machine.

Remove the bobbin. Cut the thread connecting the bobbin and the spool, then remove the bobbin from the bobbin winding shaft. Push the bobbin winding shaft to the left. You should be able to remove the bobbin by lifting it straight off.

Threading the Needle

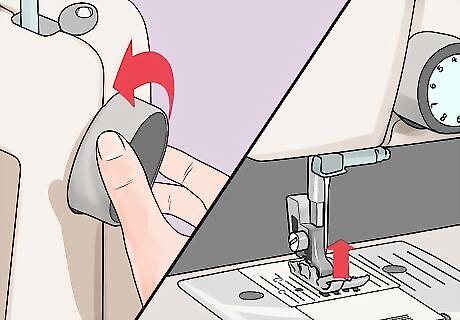

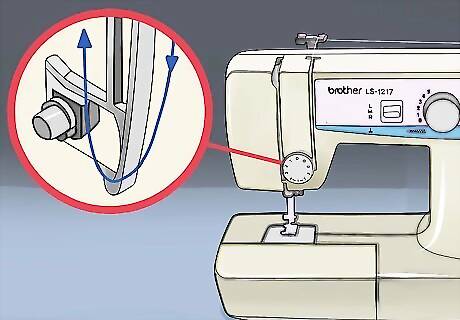

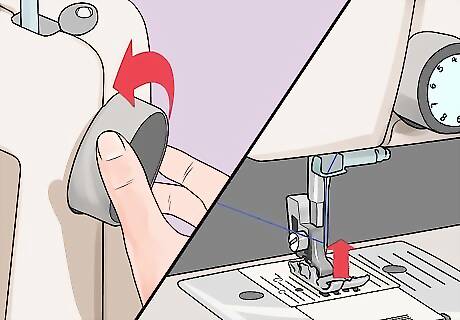

Raise the thread take-up lever. Turn the balance wheel at the right side of the machine until the thread take-up lever in the left front channel reaches its highest position. Note that the machine should be off at this time to reduce the risk of injury or damage. Turn the balance wheel counterclockwise, or toward you. Do not turn the wheel away from you. Raise the pressure foot by lifting the presser foot lever at this time, as well.

Load the spool of thread. Place the spool of thread on the spool pin at the top of the machine. You may need to pull up the spool pin before doing this. Note that the spool of thread should sit so that the tail you remove comes off from the back, rather than the front, causing the spool to spin counterclockwise as it unwinds.

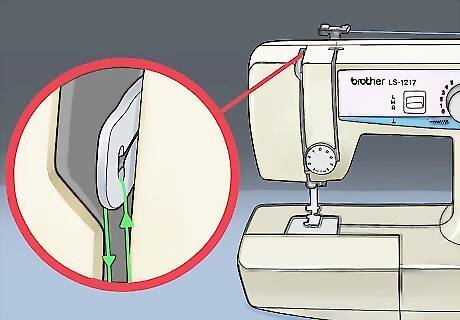

Draw the thread into the right channel. Pull the thread across the top of the machine and through the upper thread guide before drawing it down into the right front channel. The upper thread guide is the hooked piece of metal attached to the bobbin winding tension disc. The thread should pass into the right channel at straight angle, not at a diagonal.

Wrap the thread around the thread tension discs. Wrap the thread behind and around the thread tension dial in between the two front channels. You may need to apply light pressure to the thread above the right channel as you do this. Wrap the thread around this dial from right to left. Make sure that it picks up the check spring to the left of this dial before continuing.

Guide the thread around the take-up lever. Pull the thread up through the left channel, over and through the hook of the take-up lever, then back down the left channel on the other side of the lever. The thread should be to the right side of the take-up lever before you hook it into that lever. Afterward, it should come back down to the left side of that lever. The thread should naturally slip into the hook of the take-up lever as you wrap it around the back of that lever.

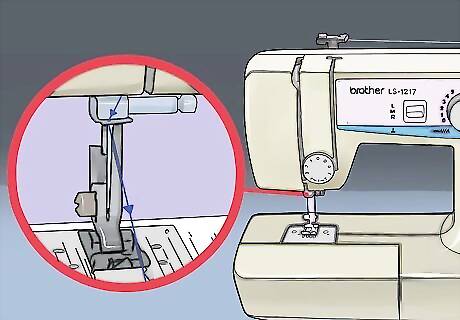

Hook the thread into the final thread guide. Draw the thread down toward the needle, then slip it into the final thread guide just above the needle itself. This thread guide looks like a small bar standing horizontally across the top of the needle. Slip the thread into the opening of that bar, sliding it into the slot until it reaches the inside bend.

Thread the eye of the needle. Draw the thread through the needle, working from front to back. Leave a tail measuring 2 inches (5 cm) long. Position this tail so that it sits to the back of the machine.

Loading and Drawing Up the Bobbin Thread

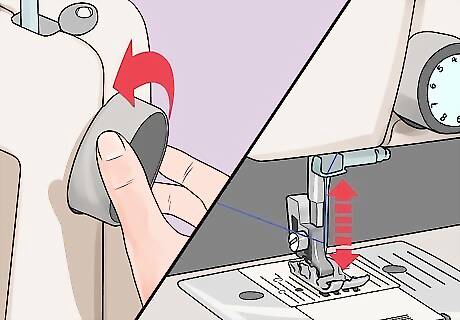

Raise the needle. Turn the balance wheel at the right side of the machine, doing so until the needle reaches its highest position. Note that the machine should be turned off at this point to minimize the risk of injury or damage. Only turn the balance wheel toward you, moving it counterclockwise. Do not turn it away from you. If necessary, raise the presser foot lever at this time, as well.

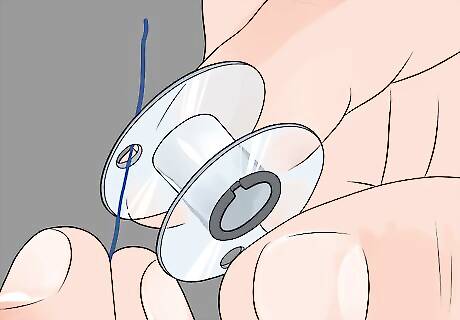

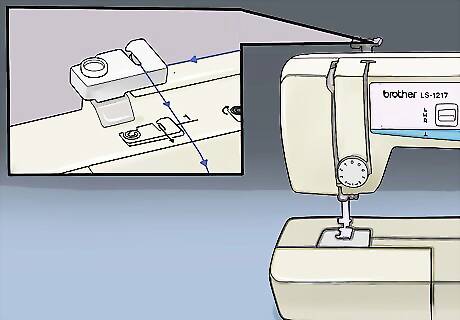

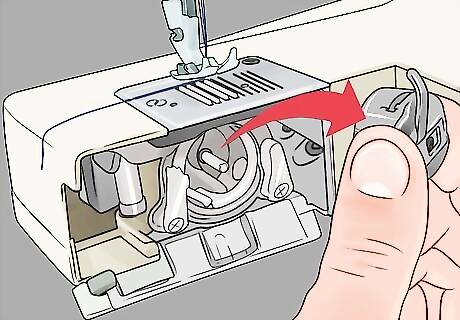

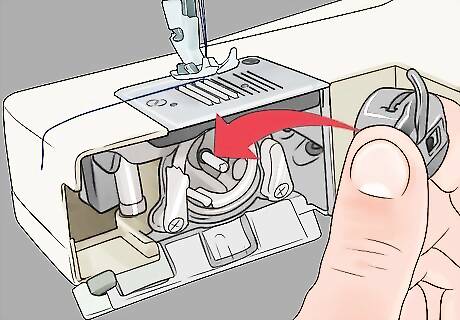

Remove the bobbin case. Open the shuttle cover and lift the bobbin case out of the machine by pulling on the bobbin case latch. The shuttle cover should be located behind the extension table and on the front of the machine. Pull the bobbin case latch toward you. You should feel the case loosen from within the machine. Continue pulling the latch toward you to remove the case from the machine completely.

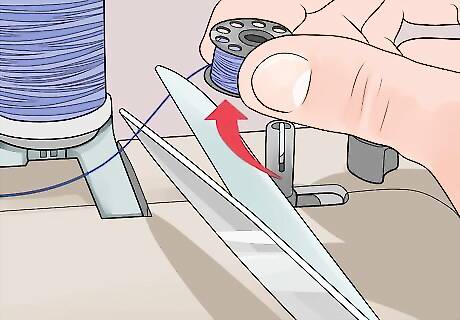

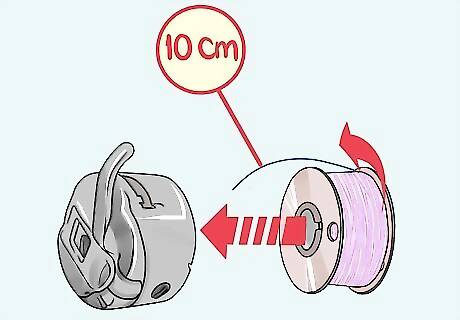

Insert the bobbin into its case. Slide the bobbin into the bobbin case and slip the bobbin thread tail through the slot in the case. Unwind roughly 4 inches (10 cm) of thread before placing the bobbin in its case. This is the tail of thread you'll need to work with in this step. Hold the bobbin case so that the hook of the latch rests on your thumb. Hold the bobbin so that thread appears to wrap around in a clockwise rotation. Slip the bobbin into its case with the tail of thread hanging out. Pull the tail of thread into the natural groove of the case, sliding it until it fits under the spring clip and through the thread guide hole (delivery eye) of the case.

Return the case to the machine. Hold the bobbin case by its latch again, then insert it back into the machine. Release the latch after the bobbin case locks in place. The latch of the case should fit into the notch at the top of the shuttle race inside the machine. If loaded properly, the case should not be able to move around inside the machine.

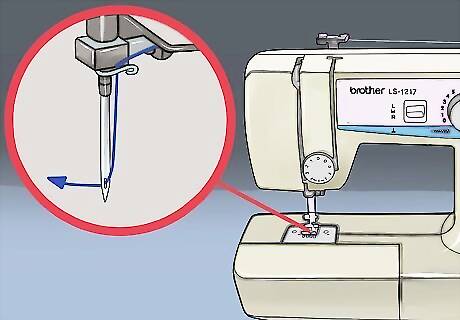

Cycle the needle once. Turn the balance wheel at the right side of the machine, moving it toward you (a counterclockwise rotation). The needle must sink into the base of the machine and rise back up to its highest position again. Firmly hold the end of the upper needle thread with your left hand while turning the balance wheel with your right, applying a light amount of tension to that thread in the process. Do not turn the balance wheel away from you (a clockwise rotation). If done correctly, the upper thread should catch the lower thread during this process, bringing the lower thread out from the base of the machine in a large loop.

Catch the loop. Use your finger to carefully catch the loop of thread you just pulled up, breaking open the loop in the process. You should see two separate tails of thread: one extending from the needle (the upper thread) and one extending out from the base of the machine (the lower thread).

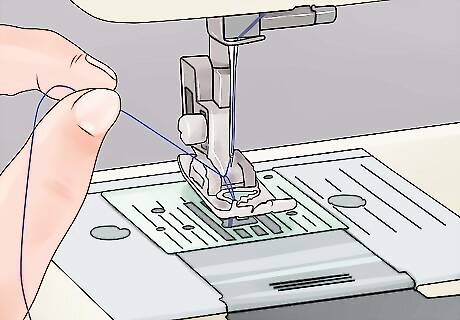

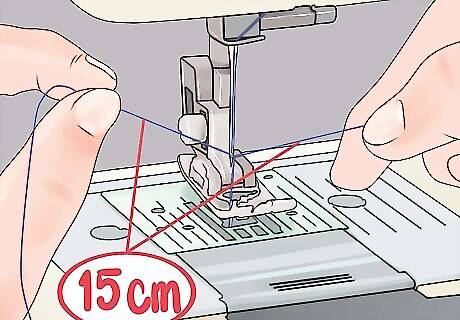

Straighten out both threads. Pull on both threads separately until you have a 6-inch (15-cm) tail of each. Position both tails so that they extend out toward the back of the machine. Both threads should fall straight behind the presser foot. The upper thread should pass in between the toes of the presser foot.

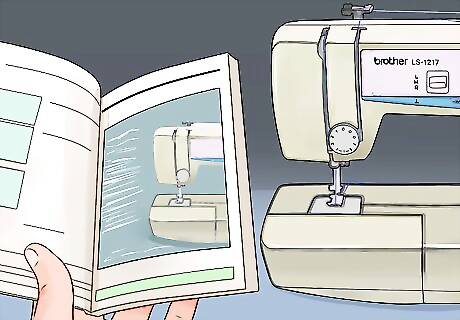

Double check. Read through the steps again and check the way that both the top and bottom threads have been prepared. If everything was done correctly, the machine is now threaded and should be ready to use.

Comments

0 comment