Long Wait For Your New Car? Laptops Out Of Stock? Can’t Buy A PlayStation 5? Blame The Chip Shortage

views

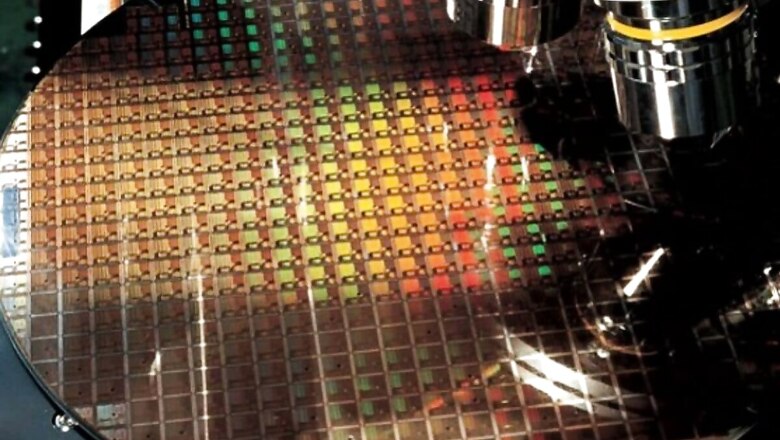

Semiconductors. You may never have realized this, at least till now maybe, but these good old semiconductors are the very backbone of pretty much everything around you. At least the non-living things. Be it your laptop or PC, your TV, your smartphone or even the good old Wi-Fi router you have at home, everything uses these to work. As does your car, which is parked outside. If you have been noticing how the laptop that you have been eyeing has remained out of stock for the past few months, or how your annoying relatives keep complaining that the car they booked a few months ago still has a waiting period for another few months, you can now draw a parallel between these two occurrences. We world is in the midst of what can simply be called a semiconductor shortage, and that’s how it is expected to be, at least for the next few months.

The shortages of semiconductors are impacting everyone. In India, there are incredibly long waiting times being quoted by dealerships if you walk in now to book a new car—even longer if the car is very popular and in high-demand. If you aren’t able to get your hands on a new Sony PlayStation 5 or Microsoft Xbox Series X or Series S gaming console, that’s also because there are very few chips to work with. Smartphone makers including Apple have said that sales of new phones have been impacted by the shortage of components. Qualcomm, the world’s largest chipmaker for smartphones and mobile devices, has also said that the industry’s reliance on a handful of semiconductor manufacturers is hurting business. Before we try to understand why we are in the mess we are in, it is important to see the criticality of semiconductors in our lives.

What are semiconductors And Just Why Are They So Important?

I am absolutely not an expert at the science of semiconductors. Best to let tech giant Hitachi explain what semiconductors are—”Semiconductors possess specific electrical properties. A substance that conducts electricity is called a conductor, and a substance that does not conduct electricity is called an insulator. Semiconductors are substances with properties somewhere between them. ICs (integrated circuits) and electronic discrete components such as diodes and transistors are made of semiconductors. Common elemental semiconductors are silicon and germanium. Silicon is well-known of these. Silicon forms most of ICs. Common semiconductor compounds are such as gallium arsenide or indium antimonide.” This is why these semiconductors are an integral part of pretty much every electronic appliance that you may use at home, or for any infrastructure that you may use inside or outside your home.

What all use semiconductors and silicon chips? Answer: A Lot Of Things

The list is long. Your smartphone, your TV, your refrigerator, the new AC that you purchased ahead of the summer, laptops and PCs, smart speakers, tablets, gaming consoles such as the Sony PlayStation 5, lamps and bulbs, children’s toys, washing machines, rice cooker, microwaves, water purifiers, air purifiers, induction cookers, fast chargers, wireless chargers, Bluetooth speakers, water heaters, your internet modem and Wi-Fi router—pretty much everything you see around you in your home uses semiconductors to be able to do whatever it is that they are meant to do. It seems that most things, except for your bottle of moisturizer, the shower gel and the cutlery on the dining table, use some sort of smartness from silicon chips.

Step out of your home, and there are crucial semiconductors in your car, your bank’s ATM machine, communications infrastructure that your mobile company has set up for 3G and 4G, that 5G network you keep demanding, public transport, the backend systems of apps that we all use on your phone, that credit card machine you swipe your card with to complete a shopping expedition at a store, a lot of the hospital equipment, and more. And this is just a pretty concise list, while at it.

During the quarterly earnings call in January which saw Apple set revenue records and robust sales including of the newest iPhone 12 series, the company was still feeling the impact of supply chain constraints. Apple CEO Tim Cook told reporters at the time that “semiconductors are very tight” along with short supply of other components too. “The current chip shortage all starts with the unprecedented demand for personal computers and peripherals as the globe worked and attended school from home,” Patrick Moorhead, founder of Moor Insights, told CNBC last month.

So, why are we in this situation?

There isn’t any one reason for why we are in the midst of a global semiconductor scarcity. Yet without doubt, things started to unfold as soon as the COVID pandemic rolled into town. As the world locked themselves indoors, with remote working and remote education becoming the way of life, the demand for laptops, PCs, phones, tablets and peripherals such as monitors, modems and Wi-Fi routers, printers, webcams and work from home (WFH) accessories saw a global surge in demand. Computing device makers were struggling to keep up, at least in the initial few months of last year, and there are still some gaps in the product lines with limited availability of certain products.

“The shortage in the semiconductor industry is across the board,” Qualcomm’s CEO Cristiano Amon, had warned in February that it isn’t just a shortage of the newest or the fastest chips, but every chip that’s being used in tech products, appliances and cars. As the pandemic shut everything down around the world, a lot of companies scaled back on production in the first few months of 2020. They cut orders. These included tech and automobile companies, many of whom didn’t foresee the demand return to normalcy, as it happened. More so in the case of auto companies, because demand bounced back much sooner than expected. In some cases, such as computing devices and home appliances, not just a normalcy but significantly higher demand. This left them with a major backlog to catch up to, as they tried to buy enough components and raw materials to get their own production lines working at full steam. Everyone’s queueing up again, but there aren’t enough components to go around. The problem that happened was—in case someone cut orders in the first half of 2020 found themselves at the back of the queue once they discovered that the consumer spending is back again, since other tech and health companies took the orders they vacated.

Global Climate Hitting Semiconductor Manufacturing

You probably wouldn’t have realized this, but two extreme climate scenarios unfolding in different parts of the globe have hit semiconductor production hard. And that’s leading to a further backlog. For large parts of February, Taiwan Semiconductor Manufacturing Company (TSMC) and Samsung struggled with manufacturing at their facilities in Taiwan due to a drought in the region. Soon after, Samsung’s S2 Fab in Austin, Texas has to slow down production due to the extremely cold weather which blew through the state, impacting electricity supply. Reports emerging from Taiwan indicate that weather forecasts suggest the dry season may last until May, with March being drier than usual as well.

This also indicates a geographical concentration problem. More than 70% of the world’s semiconductors are manufactured by TSMC and Samsung, that’s according to market share numbers from Q2 2020. Both of these manufacturers rely heavily on their facilities in Taiwan.

Donald Trump Came, Donald Trump Did Something, Donald Trump Went Away

While the pandemic has certainly been the biggest disruptor, the semiconductor shortage may not have been this acute if it wasn’t for former US President Donald Trump’s trade war with China that had tech company Huawei in the middle of it all. As new regulations began to roll in, Huawei and other Chinese tech companies knew that sanctions would impact their ability to purchase chips and components for products it may want to sell in other countries. Thus, the reported stockpiling, for their 5G smartphones and tech products. The trade war also meant US tech companies couldn’t but chips from the likes of the Semiconductor Manufacturing International Corporation based in China—the company was blacklisted by the Trump administration.

It was October last year when Bloomberg first reported Huawei quietly stockpiling critical chips to keep supplying the Chimene mobile networks with 5G technology for the next 12 months or so, at least. “Taiwan Semiconductor Manufacturing Co. began ramping up output in late 2019 of Huawei’s 7-nanometer Tiangang communications chips, the most crucial element in 5G base stations, people familiar with the matter said. The Taiwanese contract manufacturer eventually shipped more than 2 million units at Huawei’s behest ahead of the sanctions cutoff last month,” the report said.

The Bitcoin Problem: Of Course, Its 2021, Bitcoin Has To Insert Itself In Everything

Bitcoin and cryptocurrency is in vogue this year. Fair enough, but the problem is, crypto needs a lot of processing power to work. That has meant cryptocurrency miners are buying graphics cards, otherwise meant for gaming on PCs in large numbers. So much so that Nvidia has to cut down the hash rate (mining efficiency) of the GeForce RTX 3060 graphics card in half for Ethereum miners, via a software update, to ensure there is enough supply for gamers. All this has also meant that prices of graphics cards, alongside dwindling availability, have shot up. “Please keep a close eye on bitcoin prices, then you can get the price trend of graphics cards,” the South China Morning Post reported a vendor as saying, earlier this month.

Is There A Light At The End Of The Tunnel?

Unlikely, that there will be a respite in the short term. Though steps are being taken to ease the supply constraints. Last month, US President Joe Biden’s administration and Taiwan’s Economics Minister Wang Mei-hua held their first economic dialogue days after the Biden administration took charge. Part of this dialogue were tech companies as well, including Qualcomm, Corning and TSMC, reports Nikkei Asia. The report says Taiwan has asked TSMC, United Microelectronics, Vanguard International Semiconductor, and Powerchip Semiconductor Manufacturing Co. to help ease the unprecedented chip shortage, which is particularly hurting the auto industry. How quickly the scaling up can happen, remains a concern.

It is being reported that automakers and medical device manufacturers have asked the Biden administration to subsidize construction of new semiconductor manufacturing facilities in the US, even as TSMC has shown intent for investing in Arizona. That being said, setting up a semiconductor fabrication facility is a costly and time consuming process—it takes up an investment of around $10 billion from the outset and takes around 5 years to become operational.

Read all the Latest News, Breaking News and Coronavirus News here

Comments

0 comment