views

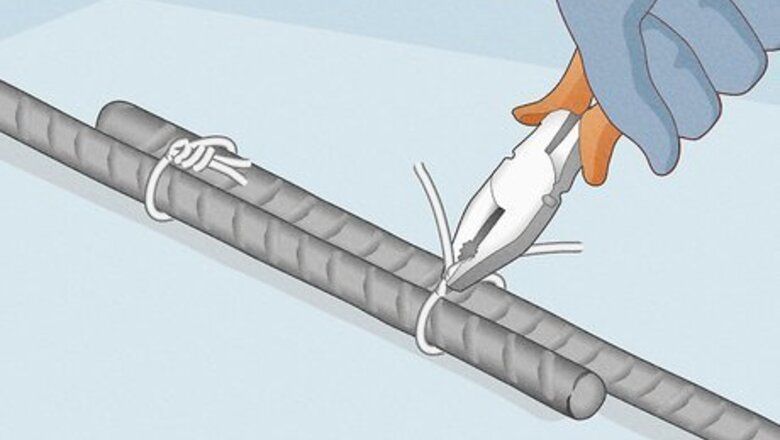

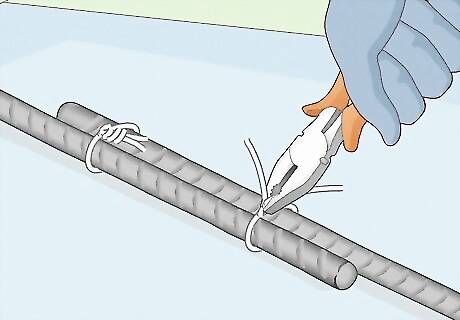

Splice tie for parallel rebar

This simple tie works well when a single piece of rebar isn’t long enough. Start by overlapping the ends of the 2 pieces of rebar by at least 2–3 in (5.1–7.6 cm). Feed the wire under both rebar pieces where they overlap. Twist the wire ends together twice by hand against the rebar. Grip your pliers right on the existing twist, squeeze tightly, and spin the pliers all the way around 4-5 times. To get rid of excess wire, snip off the free ends with the cutter on the pliers, then bend and fold any remaining wire down and out of the way.

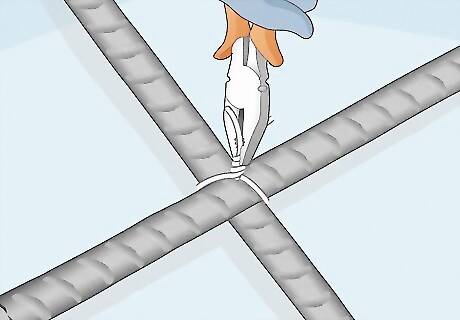

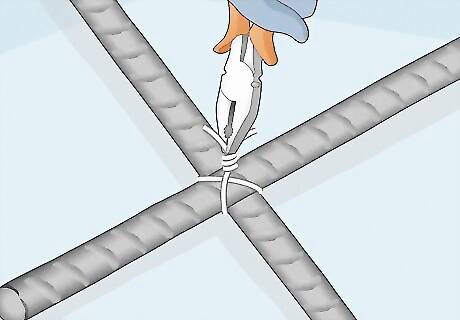

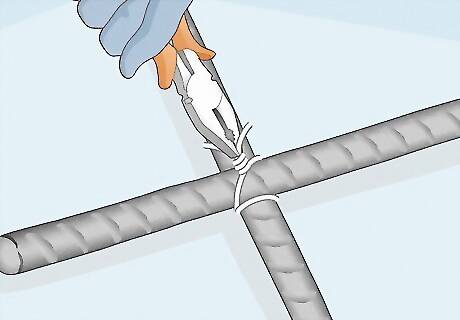

Single tie for intersecting rebar

This is a good, fast option when you don’t need a super-secure tie. Begin by feeding the wire under the intersection point of the 2 pieces of rebar so that the free ends point upward on opposite sides of the intersection. Twist the wire 1-2 times by hand firmly over the top of the rebar intersection. Grip the twisted wire with your pliers and make 4-5 more twists. Snip off the excess wire and bend the twisted wire out of the way. Single ties are usually suitable for rebar intersections made on the ground. For vertical intersections, such as when forming a concrete wall, use a stronger tying option.

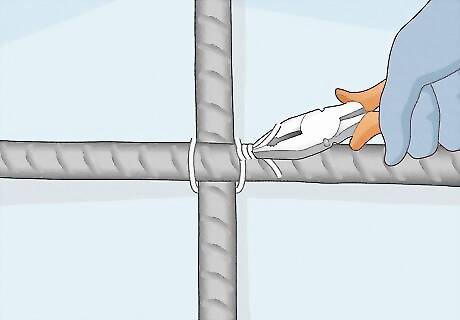

Figure 8 tie for intersecting rebar

The figure 8 locks a rebar intersection in place more securely than a single tie. Start by bending the wire into a U-shape and feeding it under the bottom piece of rebar, right against the intersection with the top rebar piece. Create an X with the free ends of wire over the top piece of rebar, then wrap one of the free ends all the way around the bottom piece of rebar. Twist the wire ends together by hand and with pliers right on top of the X intersection. The figure 8 tie is a good choice for both horizontal and vertical rebar intersections.

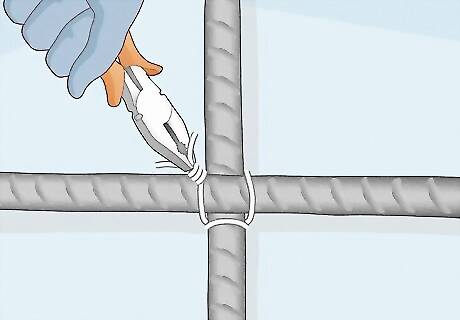

Wrap tie for rebar intersections

Wrap ties, like figure 8 ties, are much stronger than single ties. To begin, bend your wire into a U-shape and feed it under the piece of rebar that’s on the bottom, right next to the intersection with the piece of rebar that’s on the top. Wrap one end of the wire all the way around the bottom piece of rebar. From this point, use the 2 free ends of the wire to wrap a basic single tie over the intersection of the rebar. The added twist around the lower piece of rebar helps to keep it from sliding up or down against the upper piece of rebar.

Saddle tie for rebar intersections

This tie, also called a U-tie, is great for vertical rebar connections. Start the tie by bending the wire into a U-shape. Run it under the bottom piece of rebar, just next to the intersection. Bring one of the free ends up and over the top piece of rebar, then under the bottom piece of rebar, both times keeping right next to the intersection. Run the same free end back up over the top piece of rebar so it meets up with the other free end. Twist the ends together by hand and then with your pliers. Once you tighten this tie, both pieces of rebar will remain securely connected in nearly all conditions.

Wrap and saddle tie for intersecting rebar

Combining the wrap and saddle ties makes the strongest rebar connection. Start with a wrap tie, looping the wire under and all the way around the bottom piece of rebar, right next to the intersection with the top piece of rebar. From there, do a saddle tie (or U-tie), going under, over, under, and over as you work the wire around the rebar intersection. Twist the wire tight with your fingers and then pliers. This is the best option if you want to build a rebar framework on the ground and then hoist it into a vertical position. The wrap and saddle tie combo will keep the rebar intersections firmly in place.

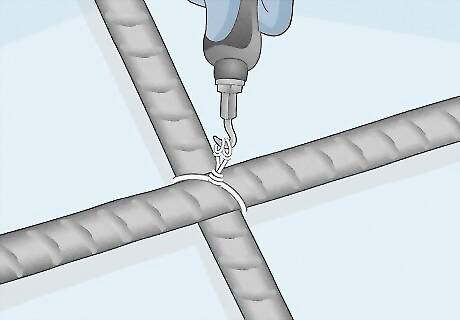

Rebar “bag ties” with twisting tool

This may be a good alternative if you have lots of rebar to tie. Bag ties are pre-cut lengths of rebar-tying wire with pre-made loops at each end. Tie them around rebar in any of the typical ways—splice tie, single tie, etc.—but use a battery-powered, crank-powered, or hand-powered twisting tool to tighten them. Feed the hook end of the tool through the 2 loops and engage the twisting mechanism to tighten the wire against the rebar. A battery-powered twisting tool does the job with the push of a button, while a crank-powered tool requires you to pump the handle of the tool with one hand while holding it in place with the other. With the most basic option, the hand-powered twisting tool, you rotate the offset handle with one hand while steadying the tool with the other. Look for bag ties and twisting tools wherever rebar and related tools and equipment are sold.

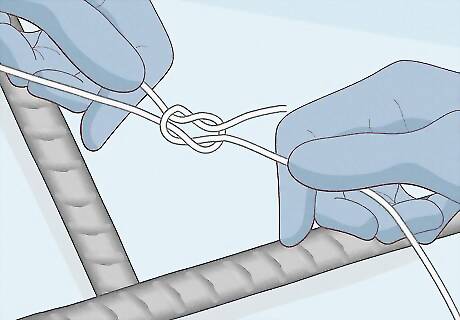

Reef knot for wire joining

Connect 2 ends of things like jewelry and fencing wire with a reef knot. Start by making a J-shaped hook at the free end of each wire. Feed the right-side (R) wire’s hook over, into, and under the left-side (L) wire’s hook. Bring the free end of the R wire up and over the shank (long) and free ends of the L wire. Direct the free end of the R wire under, over, and through the hook of the L wire. Pinch the shank and free ends of both wires together. Pull the pinched wire pairs in opposite directions to tighten the knot. Reef knots are also known as square knots. Reef knots are a good choice for joining 2 pieces of wire that aren’t under tension—for instance, 2 lengths of fence wire that haven’t already been tightened.

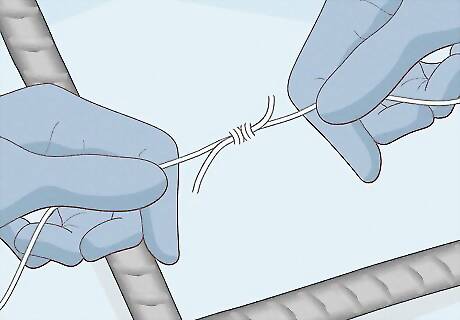

Double love knot to join wires

Interlocking a pair of overhand knots makes a strong wire connection. Make an overhand knot in one of the wires by bending the free end of the wire back over itself to make a loop, then passing the free end of the wire through the loop. Feed the free end of the second wire through the loop of the knotted wire. Tie an overhand knot in the second wire that links through the first wire’s loop. Pull the free ends of both wires in opposite directions to tighten the knot. The double love knot is also called a double overhand knot because it uses 2 overhand knots. While different in style from a reef knot, it’s similarly useful for connecting 2 pieces of wire that are not under tension.

Comments

0 comment