views

Prep time: 4-6 weeks

Yield: Approximately 2-3 L (0.5 - 0.8 gallons) rum

Making the Mash

Begin by placing 20 L of water in a clean boiler. The operative word is clean. The slightest bit of contamination can spoil the rum. Before you start, make sure you're dealing with the cleanest ingredients and a sanitary area. Clean and then submerge any utensils you will be using in boiling water. Turn the heat off the boiling water and soak your pot or barrel in the near-boiling water. Then dump the water. This will help kill off any potentially harmful germs.

Dissolve both the sugar and molasses in 20 liters of water over medium heat. The sugar will dissolve easily, but the molasses will be tougher dissolve, as it is very sticky. Try not to boil the water. Continue to let it heat up until bubbles just start to form, and then turn the burner off.

Cool the solution to 28 °C (82 °F) and add the hydrated yeast. You may find it helpful to take out about 1 liter of the mash in a jug first; try dissolving the yeast in the smaller jug. Then, when the mixture begins to foam up, incorporate with the rest of the wort.

Fermentation

Allow solution to ferment at 25° C (77° F) until the airlock on your pot stops bubbling. The yeast needs heat to keep converting sugar to alcohol. So be sure to store the wash in a warm place or keep the room artificially heated. The airlock on the pot will let the carbon dioxide out without letting oxygen in. It should take about 24 - 48 hours for the airlock to stop bubbling. The airlock is a really important piece of the fermentation process. You can make an airlock yourself pretty easily, or you can buy one inexpensively. Either way, be sure the airlock fits well and doesn't let additional air into the container. Why is it important that no air gets into the wash? The yeast feeds on oxygen from the sugar molecules, leaving ethyl alcohol behind (and spitting out carbon dioxide). If the yeast has a continuous supply of oxygen to eat, it won't be effective scavenging the oxygen from the sugar molecules.

Once airlock has finished bubbling, allow the mash to sit for 3-7 days. You can use a hydrometer to test when the mash is ready. Hydrometers measure the ratio of a density of a liquid to the density of water. Measure once a day starting on the day when your mash should be finished. Take a bit of mash out of the container and put it into a graduated cylinder. Float the hydrometer into the cylinder, gently swirling the cylinder to release any bubbles. When you get the same reading on the hydrometer for three days straight, your wash is ready to distill.

Knock your yeast down by lowering the temperature. At this point, your yeast may still be on the surface of your wash. Allowing the yeast to enter the still during distillation will cause bad smells and flavors. To knock the yeast down to the bottom of the mash, you should move your mash to a cool place — ideally, 10° - 14° C (50° - 57° F) — and wait up to two days. At this point, you can siphon your wash directly into the still or rack it and save a part of the yeast for another batch in the refrigerator.

Distillation

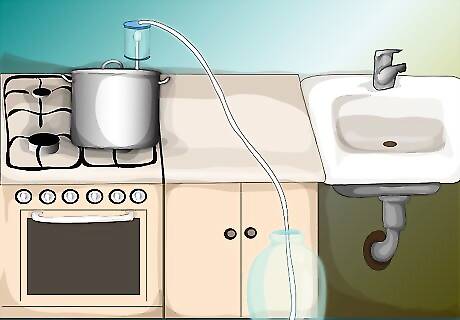

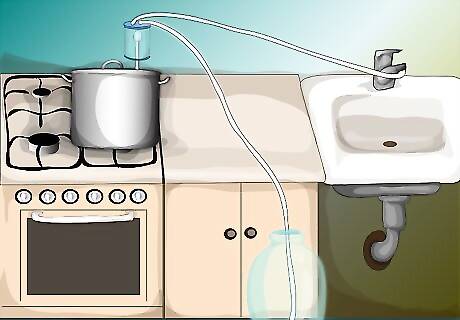

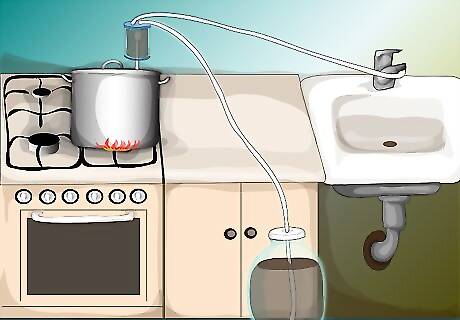

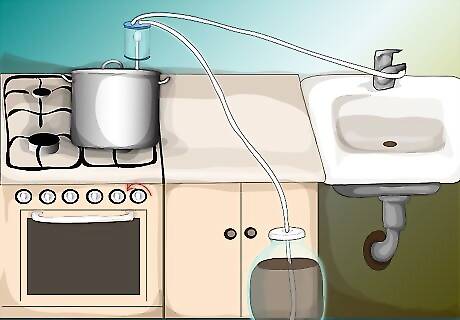

Place a collection vessel under the distillate valve to catch your alcohol solution. It's very important that all connections are tightly sealed and fit well.

Connect a water source to coolant input. You want a water source to cool the alcohol vapor. As the alcohol vapor cools, it condenses into liquid ethanol. This will then drip from the condenser into a collection vessel.

Now siphon the solution into the still. Be sure to siphon the mash carefully, avoiding the bottom, where the yeast collected. A siphon is a tube or conduit bent into legs of unequal length, for use in drawing a liquid from one container into another on a lower level. Siphoning works by placing the shorter leg into the container above and the longer leg into the one below. The liquid is forced up the shorter leg and into the longer leg by the pressure of the atmosphere.

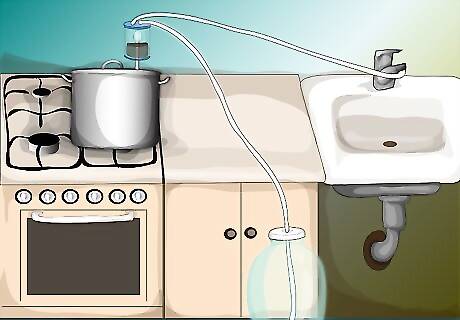

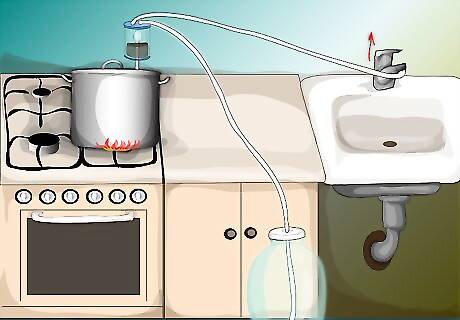

Begin slowly bringing the solution to a boil. For rum, a slow boil is best; no need to crank it up. Begin running cold water once the solution reaches between 50-60°C (122-140 °F). The solution will start distilling when clear drops of liquid start to exit the spout into the collection vessel.

Discard the first 100mL (3.38 fl. ounces) of clear liquid. This is called the "heads," and is routinely discarded for safety precautions. The heads contains volatile methanol, which can be lethal if ingested. Better to be safe than sorry, especially when you're distilling three liters of spirit.

Collect the next 2-3 L of distillate exiting the spout. Stop collecting once temperature reached 96 °C (204.8 °F).

Turn off the heat source, then turn off the cold water.

Open the lid to still so as to avoid creating a vacuum inside your still.

Finishing off the Rum

Age your rum in oak barrels or toasted oak (optional). Often, rum is aged in toasted oak barrels for 10 years or longer to add depth of flavor and color. If you don't have the luxury of a toasted oak barrel, or 10 years' time, you can safely soak your rum in toasted oak chips for three weeks to impart a signature taste. Filter your rum through a cheesecloth or clean cotton shirt to catch any of the wood particles.

Use water to dilute alcohol to expected proof. Depending on the reflux still, your undiluted rum can be up to 95% alcohol, which is dangerously strong for consumption. Use a dilution calculator to bring your rum down to around 45% for the best taste experience.

Add flavors of other additives to improve the taste. Make spiced rum by adding cinnamon, ginger, and cloves to the final rum mixture, soaking for 1 - 2 weeks. Some choose to add a small amount of caramelized sugar to the rum.

Comments

0 comment