views

A prominent university in Texas has developed an inexpensive, automatic and hand-held ventilator that could soon be available to doctors in the US and help them combat the coronavirus pandemic that has infected over 164,000 people and claimed the lives of 3,170 others in the country. Across the United States, hospitals are facing shortages of ventilators, some medical device makers have agreed to ramp up supplies.

But because patients diagnosed with or suspected to have COVID-19 often require breathing support, there is widespread concern that these devices won't be developed and shipped quickly enough. Texas-based Rice University and Canadian global health design firm Metric Technologies have developed an automated bag valve mask ventilation unit that can be built for less than $300 worth of parts and help patients undergoing treatment for COVID-19. The collaboration expects to share the plans for the ventilator by making them freely available online to anyone in the world.

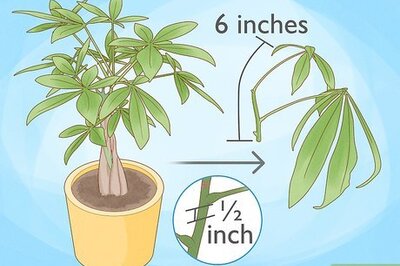

The varsity team designed and built a programmable device able to squeeze a bag valve mask. These masks are typically carried by emergency medical personnel to help get air into the lungs of people having difficulty breathing on their own. But the masks are difficult to squeeze by hand for more than a few minutes at a time.

"It's automatic, electric, and works independently of a tech," Wettergreen, a varsity professor and member of the Design Kitchen team said. "It's not designed for people who are critical cases, but rather who are in respiratory distress," he added. That delineation is important: the automated Bag-Mask Valve (BVM) would take less-critical patients off ventilators and free them up for only those in dire need. The benefit could be a game-changer for those on the front lines of the COVID-19 battle, Wettergreen said.

"When a crisis hits, we use our skills to contribute solutions. If you can help, you should, and I'm proud that we're responding to the call," said the professor. The design has caught the attention of the Department of Defense, which may authorise the Navy to utilise it in the near future. It's a huge feat for the small unit, dubbed the Apollo BVM team, whose students worked around the clock and took classes online in order to deliver the project as soon as possible.

Rohith Malya - an assistant professor of emergency medicine at Baylor College of Medicine, an adjunct assistant professor of bioengineering at Rice, and a principal at Metric Technologies - coined the name as a tribute to Rice's history with NASA and former US President John F Kennedy's now-famous speech kicking off the nation's efforts to go to the moon. "This project appeals to our ingenuity, it's a Rice-based project and it's for all of humanity. And we're on an urgent timescale. We decided to throw it all on the table and see how far we go," he said.

Malya inspired the Rice project two years ago after seeing families try to keep critically ill loved ones at the Kwai River Christian Hospital in Thailand alive by bag-ventilating them for hours on end. He expects the new Apollo BVM to serve that purpose eventually, but the need is now worldwide. "This is a clinician-informed end-to-end design that repurposes the existing BVM global inventory toward widespread and safe access to mechanical ventilation," Malya said, noting that more than 100 million bag valve masks are manufactured around the world each year.

Comments

0 comment