views

Making Arrangements to Build

Survey the area. Walk along the area where you intend to build your seawall, carrying a tape measure, notepad, and pen. Use the tape measure to track the length you need to achieve. Use the pad and pen to sketch a rough outline of your shore, taking special note of any changes in elevation or sharp curves. Finally, use spray paint to mark off 8' (2.43m) intervals where you will place your poles.

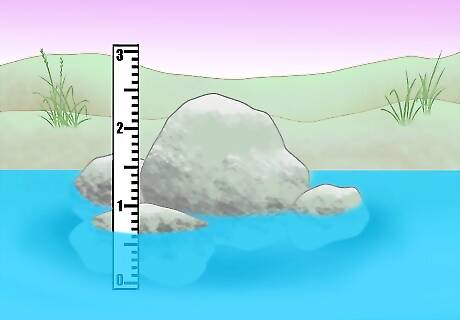

Track the high water mark. Once you know the exact location of your seawall, you can use existing rocks, posts, or other landmarks to track the height of the water. You must measure the high water mark for at least one month, during the highest tide of the day. This data will determine how high your seawall needs to be. The wall described here will be 2' (60.96cm) above ground.

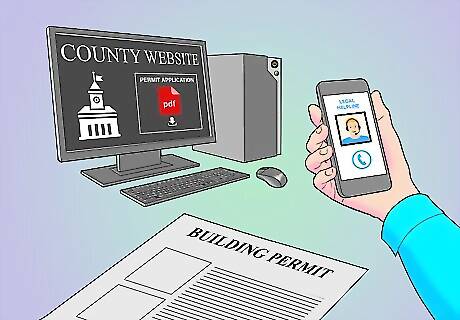

Research local regulations. Depending on the body of water you are building on, as well as the county, state, and/or country you find yourself in, there may be regulations governing what you can build. In some cases, you may need to obtain a permit, or have the area inspected before you can begin. Contact your local town, city, or county offices to determine the rules for building a seawall in your area. If necessary, obtain the proper permits.

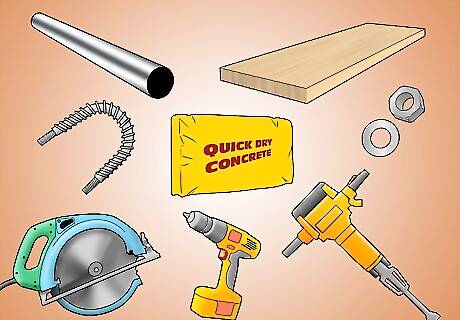

Gather supplies. To build this seawall, you are going to need some supplies, as well as some heavy machinery. The exact amounts you need will vary depending on the length of your seawall. All supplies can be purchased at a home improvement store. Look for a heavy machinery rental location near you. You will need: Metal pipes, 4’ long (1.21m), 3” (7.62cm) diameter, one every 8’ (2.43m) 2 x 12” (5.08 x 2.54cm) treated lumber, 10’ long (3.04m), 2 boards between each set of poles Threaded rebar, 4 - 10” (25.4cm) pieces per metal pipe Quick-drying concrete Galvanized nuts and washers, 8 sets per metal pipe Circular saw Drill Jackhammer

Setting Your Poles

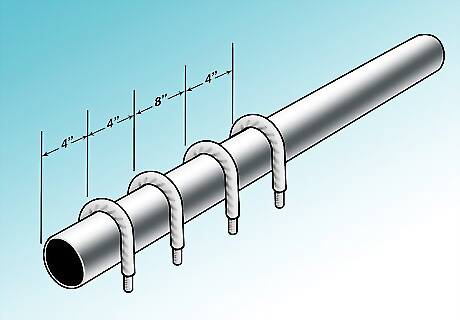

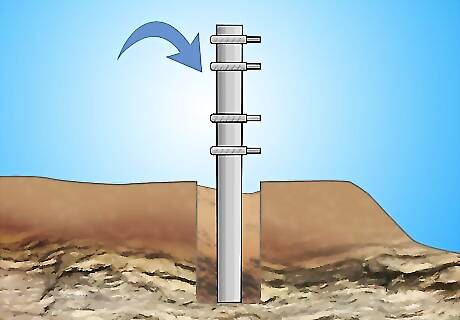

Prepare metal pipes. To begin, you are going to need to weld 4 pieces of U-shaped rebar onto each of your metal pipes (with the pipe fitting in to the “U”). You can weld these yourself, or take them to a shop. The first piece of rebar should be 4” (10.16cm) from the top of the pipe. The second piece should 4” (10.16cm) below that. The third should be 8” (20.32cm) below. The fourth should be 4” (10.16cm) inches below.

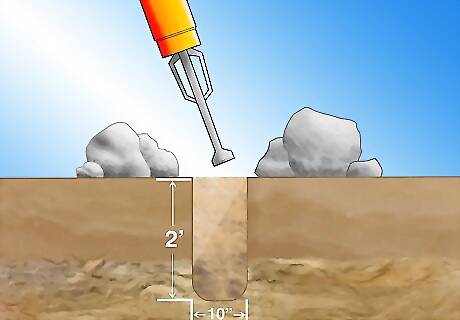

Dig holes. Digging the holes can be the most challenging part depending on the material you will be digging into. Each hole needs to be at least 2’ (60.96) deep and 10” (25.4cm) wide. Use a jackhammer to dig one hole for each metal post. If you do not have experience using a jackhammer, it is best to hire someone to help you.

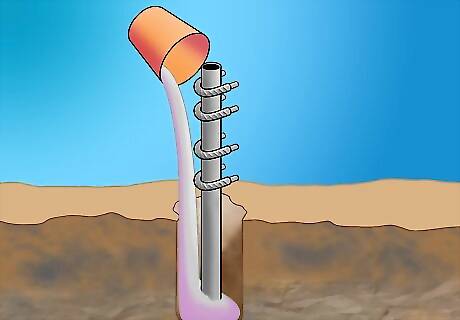

Set poles. Position each of your poles into the holes that have been dug for them. Using a level, try to make sure that your posts are even and uniform with one another. Use your jackhammer to adjust the depth of the holes, if need be.

Pour concrete. Once your poles are properly positioned, pour enough quick-drying cement to completely fill each hole. Allow 24 hours for the concrete to set. If your holes are filled with water, you will need to use a sub-pump (or simply a bucket) to remove the water before adding concrete.

Installing Lumber

Cutting your lumber. Now you will measure and cut your boards. Your wooden boards are 10’ (3.04m) long. You will 2 of these to fill each (approximately) 2 x 8’ (60.96 x 243.8cm) space between each set of poles. You metal poles are all 4’ (1.21m) long, with half of each buried in the ground. It will require 2 - 2’ x12” (5.08 x 2.54cm) boards to fill this space. Use a circular saw to cut these boards (originally 10’/3.04m long) to the proper length (approximately 8’/2.43m). Even though you set your poles 8’ (2.43m) apart, it is important to measure each space and each board individually before cutting. Changes in the shoreline can cause discrepancies.

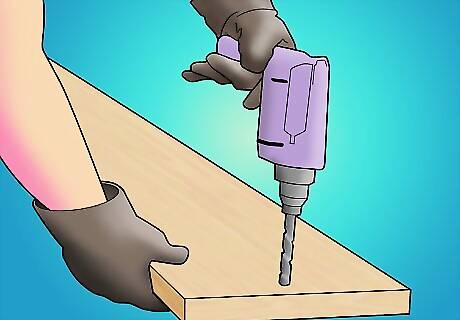

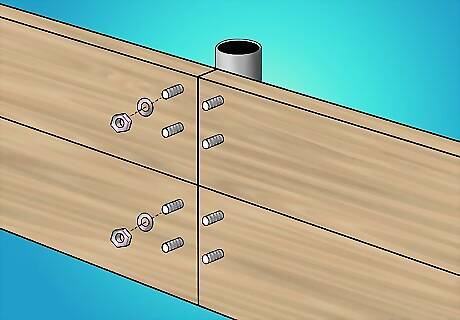

Drill holes for rebar. Now you will line up each board with each set of poles and mark the locations where you will drill holes for the rebar to pass through. Each board will have 2 holes drilled on either side. Once again, be sure to specifically measure each board to each piece of rebar before you drill.

Install boards. Fit the boards onto the poles by sliding each piece of rebar into the hole that has been drilled for it. This is not so easy, and will require at least 2 people. Install your lumber so that it is flush with the post. Then twist a nut and washer onto each piece of rebar to secure it. You may need to bend or reposition the rebar in order to make it fit through the holes in your lumber. You can accomplish this by sliding a 2-foot piece of hollow conduit over each piece of rebar, using it to bend the rebar to fit. At the end of the project, you may want to remove excess rebar with a reciprocating saw.

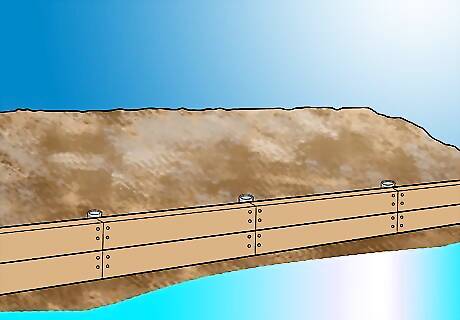

Fill in the land side. Fill in the land side of your seawall with rocks and large gravel, to allow for adequate drainage. Cover these rocks with sand, and finally finish with a layer of topsoil.

Maintaining your seawall. It is an excellent idea to provide annual maintenance to your existing seawall. Look for broken, cracked, or rotten boards. Remove the nuts, remove the boards, and replace them with fresh wood. Your metal posts should remain in tact for 5 or more years. If they become loose, they may need to be replaced as well.

Comments

0 comment