views

Preparing the Object and Glazes

Sand bumps or imperfections off the surface. Start with an unglazed, hard ceramic object. A ceramic shop or artist might direct you to suitable objects they sell. Typically, these objects have gone through a "bisque" firing process to make it hard. If you notice any bumps on the object that aren't supposed to be there, sand them off using 100 grit sandpaper. Be sure to wipe the object afterward with a damp sponge to remove dust created during sanding. If you purchased an object intended for glazing, most if not all imperfections should be removed. When sanding a piece of bisqueware you will create dust which requires the use of a NIOSH approved particulate respirator. Use a wet sanding block or wet/dry sandpaper to avoid creating dust. If you have a clay object you made yourself, fire it in the kiln to make it hard but porous before you glaze. The exact temperature to fire your object depends on its size and type of clay, so check with the manufacturer of your clay, or if the manufacturer isn't available to you, ask the advice of an experienced potter. Wear disposable gloves while handling the ceramic object to keep it as clean as possible.

Wipe the ceramic with a damp sponge before you begin and whenever it gets dirty. Let it dry. Before you begin, and whenever the ceramic becomes dirty or you apply too much glaze, wipe with a damp sponge and let it dry before attempting to apply any glaze. Avoid rinsing or dripping excess water onto the ceramic. Use each side of the sponge sparingly to keep it as clean as possible; you may want to have several on hand. Remember, you should reduce the amount of dirt or oil on the ceramic by wearing disposable gloves whenever you handle it.

Apply wax to the base of your object, and wherever two removable parts meet. A coating of wax prevents glaze from sticking to the base of the ceramic, where it would "glue" your object to the base of the kiln. For the same reason, apply the wax to the rim where a lid touches, or anywhere else two distinct pieces will touch during firing. While some potters use slightly heated paraffin wax for this purpose, a safer and less smelly option is "wax resist" designed for this purpose at ceramic shops or some art supply stores. You may apply wax resist and apply it with a paint brush. Keep this brush separate from your glazes. Crayons may be rubbed on the object to create a wax coating, but there is a possibility that the colors in the crayon wax end up on your pottery. If you are glazing pottery with children, you may find it easier to skip this step and hot glue the children's glazed objects to a clay disc immediately before firing, in order to catch dripping glaze. You may also simply sponge off any excess glaze from your piece or mask areas with tape or contact paper.

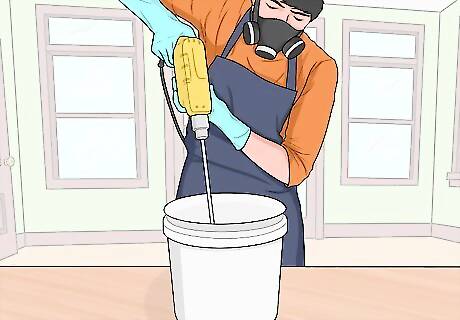

If you are mixing your own glazes, follow instructions and safety procedures carefully. A pre-mixed glaze is recommended for your first few projects (at least) due to the safety hazard and difficulties involved in mixing your own glaze. If you do decide to mix a dry glaze powder with water, follow the manufacturer's instructions carefully or your glaze may not achieve the desired characteristics. Always wear a respirator mask to avoid inhaling dry glaze particles, and work outside or in a well-ventilated room. Do not let anyone near the work area without a respirator mask. Gloves and safety goggles are recommended. Purchase the correct respirator and have yourself fit tested wearing that respirator. Many workplaces also recommended that you undergo a pulmonary fit test. While full instructions are not included here due to the variations between different glaze mixes, you will need water, a long stirring spoon, and a hydrometer to test the density, or "specific gravity", of the glaze. It also helps to have a drill mixer (used for mixing paint), a rubber spatula, two containers (sized for the final quantity of glaze), a scale, and a fine mesh sieve 60-120 mesh, depending on your recipe.

Applying the Glaze

Stir each glaze thoroughly. Even if you purchased pre-mixed glazes, they may require stirring to return them to an even consistency before you apply them. Follow the instructions on the packaging and stir until there is no sludge on the bottom or watery layer on top. You may want to deflocculate your glaze with Epsom salt. This simple process will keep the sludge forming particles in suspension. Fill a small clear cup with 1/4 cup or 60ml of water per 5 gallon bucket of glaze, slowly sprinkle Epsom salt into the water and stir, add the salt until it is saturated (when you have enough salt in the water it will no longer dissolve), when you see salt on the bottom of your cup you have reached the appropriate suspension. Add this liquid to your glaze and stir completely.

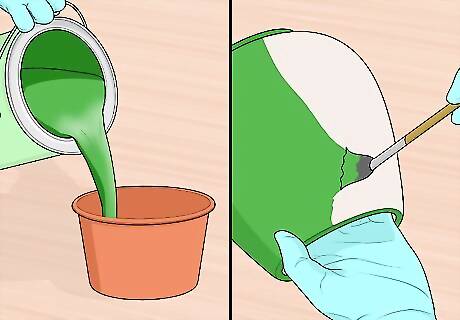

Pour each glaze into a small dish with its own brush. Keep each color separate and use different brushes to avoid mixing them. Pour them into a small container rather than dipping the brush directly into the jar. This helps keep the remaining glaze clean for later projects.

Apply the under-glaze with your brushes. Decorate the object however you wish using brushes dipped in the underglazes. This is an open-ended process, and you may choose to get creative and drip, flick, or even spray the glaze on if you want a different effect than detailed brushwork. It is also completely acceptable to cover the entire surface with a single underglaze if you want a simple, solid color. Keep in mind the final color of each glaze when you choose your design. Intentional drips are often used to great effect by ceramic artists, but be aware that thick drips may alter the texture of the pottery and could cause improper firing.

Scrape off undesired glaze with a metal object. If you apply glaze in the wrong place, or if it begins to drip, scrape it off with a knife or other metal object. Wipe with a damp sponge afterward. Do not use the knife or other object for any food-related purpose, after using it to glaze or create artwork.

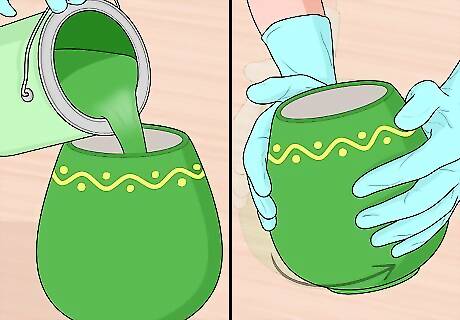

Glaze the inside of hollow containers with narrow openings. If you are glazing a ceramic pot, mug, or other object with an inside surface, it may be difficult to see inside or reach in with the brush. Instead, you could pour a small amount of glaze inside and roll the object around in your gloved hands to apply it evenly.

Let each layer of glaze dry before applying the next. Before you attempt to apply a different color of underglaze, or the final overglaze finish, you must wait for your ceramic object to dry. This will happen faster if you keep it in an area with good air flow. Do not apply a new type of glaze until the old glaze no longer appears shiny and wet, and does not smudge when your brush touches it.

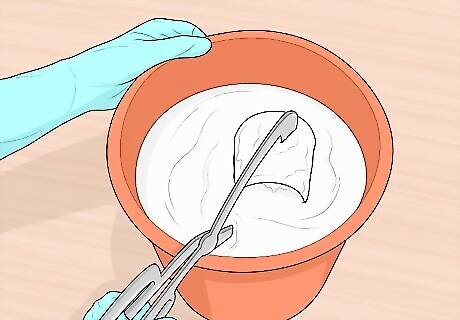

Finish the underglaze process by applying an overglaze. Overglaze creates a glossy, protective finish over the surface of the object. If you have a pair of potter's tongs, the easiest way to accomplish this is to pick up the object with the tongs and dip it in a container holding the overglaze for one to three seconds. If you would like a thicker, glossier finish, dip the object for a shorter period of time, allow to dry fully, then dip again. You may dip several times, but the total application time of all dips should be no more than three seconds. You may also brush on the overglaze. Do this so the surface is completely covered with a thin layer. It is better to allow the ceramic to dry and apply a second thin layer than to apply too much glaze in one go.

Wipe off glaze from surfaces that will stick to the kiln. Also, wipe them from surfaces that will be in contact with other ceramic objects in the kiln, such as a lid. If you covered the base or other areas with wax or another resist, it will be easy to wipe off any glaze drips that would otherwise attach your object to the floor of the kiln. Use a clean, damp sponge. If you did not use a resist, you may use an abrasive scrub pad (like those used to scrub dishes) to remove the excess glaze completely. Wipe off glaze from these surfaces after each application of glaze, before it dries. If your glaze seems runny or drips heavily, you may wish to leave the bottom 1/4inch (6mm) or more of the object's sides unglazed. Even many professional artists do this.

Firing the Glaze

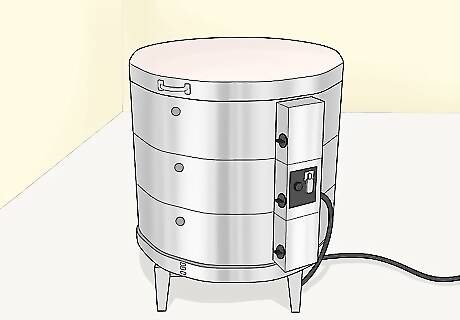

Search for a publicly accessible kiln. Purchasing your own kiln can be expensive. If you live near an urban area, there are likely pottery studios that allow anyone to rent space in the kiln. Search online for kilns in your area, or for pottery studios that you could contact and offer to rent kiln space from. If you live in the United States, this listing of kilns may be helpful, although there are many more not listed.

Seek experienced assistance if you need to purchase or operate your own kiln. If you end up needing to purchase a personal kiln, you'll probably want a more portable electric kiln. There are many factors to consider, including expense, wiring, and which additional tools to purchase. Kiln operation is complex and potentially dangerous, and you may wish to find an experienced potter to guide you through the first few times you use it.

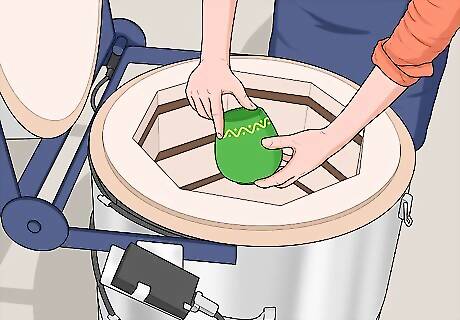

Fire the glaze according to instructions. Glazes are either low temperature or high temperature, and firing them at the wrong setting may cause the ceramic to break or the glaze to fail to set. Make sure the kiln you are using is set to the correct "cone" as described on the glaze packaging. Do not use two glazes that require different firing temperatures on the same object, or you will risk breaking the pottery. If you are dropping off your ceramic object at a studio for the employees to fire later, include a note detailing the firing temperature. Do not attach this note directly to the glazed object.

Retrieve your ceramic after several days, according to the studio's schedule. There are many different ways to operate a kiln, and some processes may require more time than others. Regardless, you should allow at least 24-48 hours for firing before your object is ready. If the kiln is used by many people, your object may not be ready for a week or two. Once it is done firing and has completely cooled, your object should be ready to take home and admire. Note that your wax should burn off in the kiln. If there is any residue from your resist materials that means you used something that did not incinerate at 1000 degrees Fahrenheit, and you will need to find a different resist material next time.

Comments

0 comment