views

Installing Fiberglass Insulation

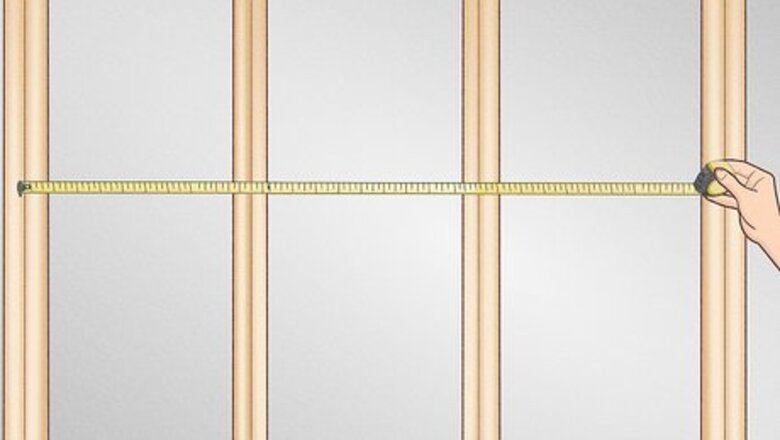

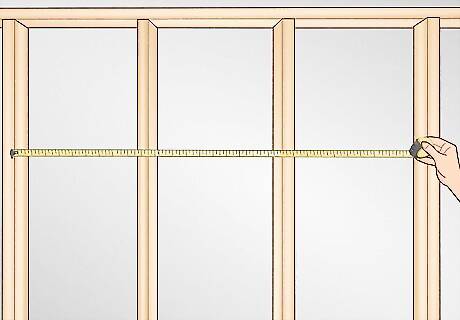

Measure the total area of the walls to be insulated. Before you buy fiberglass insulation batting, you need to find out how much you'll need. To do this, you'll need to take measurements of the total area of the individual walls to be insulated, and also the width of the space between the studs. Count up the number of wall gaps you have that need insulation and buy insulation batts accordingly. For the most part, studs will be built at uniform spacing, and batting is manufactured to fill those gaps. It should be the perfect width. Still, it's a good idea to count up the number of spaces you have and take a measurement to make sure you don't come home with the wrong size.

Choose fiberglass insulation batting. The grade of batting will vary, depending on the wall that you’re insulating. There are various grades of insulating batting for different locations in the house, so you'll need a different insulation for interior, exterior, attic or basement walls. The R-value of the batt measures the thermal resistance, so the higher the R-value, the more effectively the batt insulates. Typically, for interior walls, R-13 batts are used for 2 x 4 studs and R-19 batts are used for 2 x 6 studs. Note there are two R-value scales; US customary and metric. The US scale is approximately 5.68 times the metric scale, so R-13 in the US is equivalent to R-2.3 elsewhere. You'll also need to choose between faced batts, which have a paper "face" on one side that will cover the insulation to the outside, and un-faced batts, which are just the fiberglass.

Consider “greener” alternatives. While fiberglass is actually up to 40 percent recycled material, there’s still a common complaint about the health-risks regarding airborne fibers of spun glass in your living space. Fiberglass is safe and the most inexpensive form of insulation, but it’s certainly not the only kind. You might consider alternatives, like: Cotton. Recycled denim is regularly turned into a kind of insulation that's quite effective, and without the microfiber air problems that some people complain about with fiberglass. Mineral and sheep wool, cementitious, and cellulose-based insulation's are also common alternatives to fiberglass. You need to only use materials that have a thermal resistance rating. Insulating with things like egg crates and other recycled materials is a dangerous practice that can result in a fire.

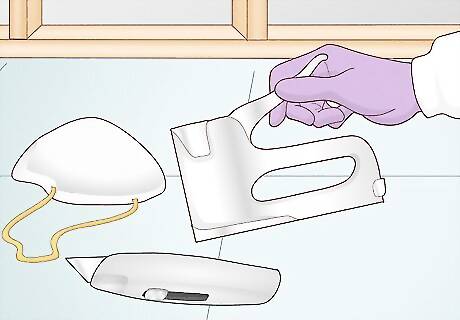

Get other tools necessary to complete the job. To install fiberglass or other insulating strips into your walls, you'll just need a few basic tools and the proper safety equipment. Make sure you've got: A staple gun Utility knife Protective gear (gloves, mask, long sleeves and pants)

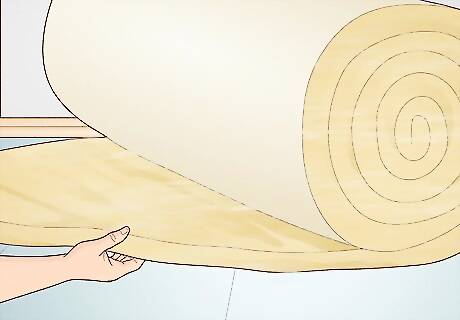

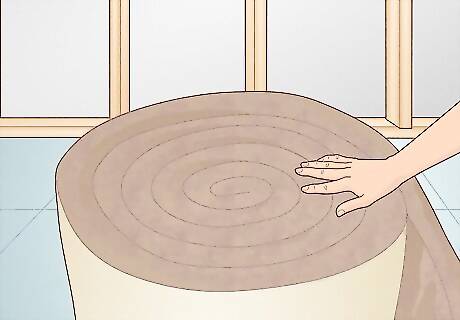

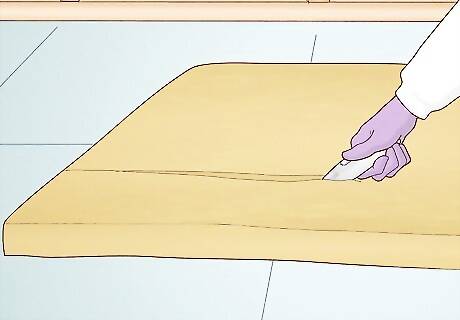

Cut batts to the appropriate height. You should have purchased insulation of the appropriate width, but you'll have to cut it to size for every space you want to fill, in terms of height. Lay the insulation out, then carefully use your utility knife to cut through the face (if you've purchased faced insulation). It's kind of hard to cut through the insulation itself, which has the consistency of tenacious cotton candy, but you can pull it apart once you get it started. When you get your insulation home, keep it wrapped up until you're ready to use it. Cutting fiberglass insulation sends lots of little fiberglass particulate up into the air, which can cause allergic reactions and breathing problems. It's also extremely itchy, and can cause rashes in some people with sensitive skin. Never touch fiberglass batting with your bare hands and always wear breathing equipment when handling it. If you come into contact with fiberglass insulation, don’t scrub your hands or face with water, which can cause micro-abrasions. Dust yourself off outside and wash your clothes immediately.

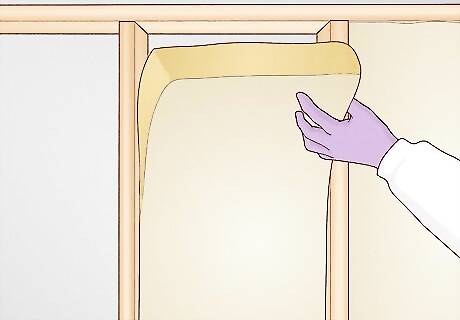

Push each batt into the gap between each stud. When you get it cut, just shove it in to the space, with the face pointing back outward, if you're using it. Try to handle it by the edges as much as possible, to keep the floating particles down. Gently tug each batt outward so it fills the gap entirely.

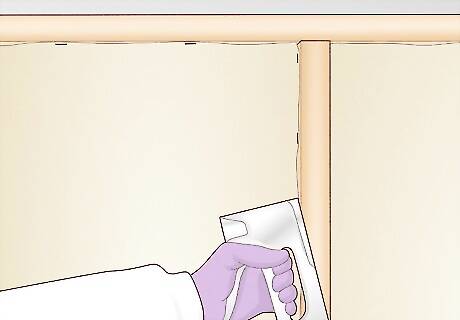

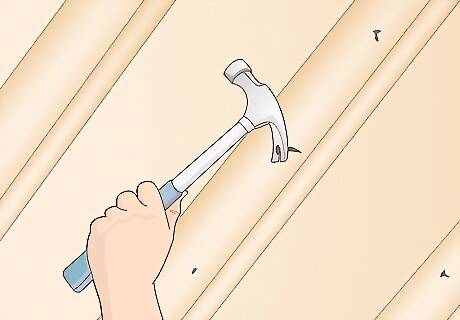

Secure the lip of the batting to each stud. Use your staple gun to secure the paper lining to the stud, roughly every 7 inches (17.8 cm). It's helpful to have an assistant hold the insulation in place, if necessary. Staple each piece securely, then move on to the next row. If you're looking for sound-dampening, it's a good idea to apply a thin line of caulk between the top plates, at the bottom plate, and around the floor of each batt. This will create a more secure seal that will keep sound from coming through.

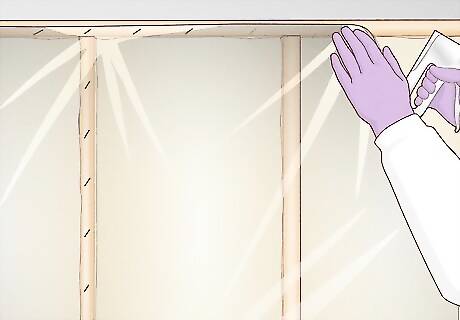

Apply vapor-retardant poly film over batting for exterior walls. To make external walls extremely insulated, it's common to apply a layer of vapor-retardant film over the insulation, to make it more secure. This will help to maximize the insulating potential of the batting, and you can find this at most home retailers. To install, you'll simply pull the film tight over the batting, stapling to the studs every foot or so, with the staple gun. Trim the excess with the utility knife.

Adding Spray Foam Insulation

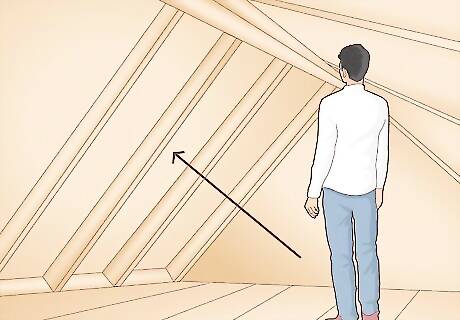

Make sure you have a suitable space for spray foam. If you want to insulate an area in your crawl space, attic, or basement, spray foam insulation might be appropriate for the job, using a low-pressure sprayer and the proper safety equipment. For the most part, roofs and other major renovation jobs require a lot of spray foam to insulate, meaning that it would probably be more cost effective to hire professional insulators with a spray rig, high-pressure applicators, and safety gear. Use spray cans of insulation for small jobs, like gaps between windows and doors, around dryer vents, fan outlets, and other plumbing. Spray cans are good for fixing small leaks, but not cost effective for insulating a wall.

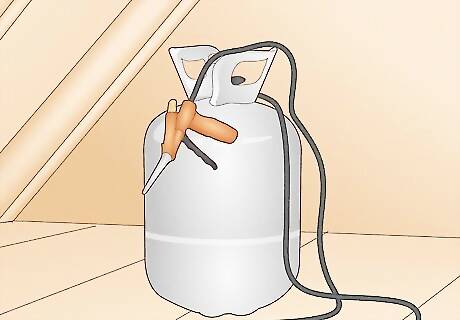

Get a low-pressure sprayer. Generally, disposable and refillable spray insulation tanks are sold as part of a spray foam insulation kit. It's not cheap, but you'll be able to quickly and easily insulate a small area. Each manufacturer will vary slightly in its You'll also need protective equipment. This means you'll need eye protection and a respirator. A full work suit would be ideal, but long sleeves and pants will also do in a pinch.

Choose between open and closed-cell insulation spray. Closed-cell insulation is rigid and dense, with a higher R-Value than open-cell. Most closed-cell spray is rated around 6.6, with open-cell insulation rated around 3.9. The advantage of open-cell is that it's super-fast and cheap, included in most individual small spray cans of foam. In wall-insulation, small holes are usually made in the drywall, into which the sprayer nozzle is inserted to fill the cavity with the spray inside the wall. For this method, open-cell is most often used, especially for ceilings and interior walls. It's sound-proof and used in the same locations as fiberglass. Closed-cell is usually used on external walls.

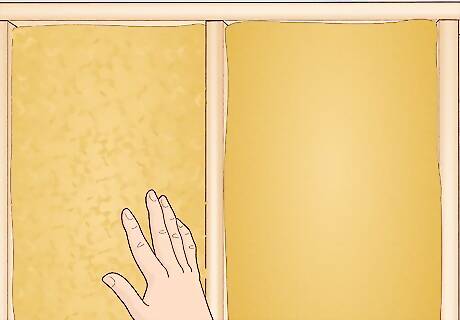

Prepare the area for insulation. Remove exposed nails, debris, and other impediments from the walls to be insulated. Identify drafting areas–seams where you feel air leaking, see daylight, or see a gap. Mark these areas with tape, or a pen to make sure you address them with the insulation. It's a good idea to cover nearby furniture or finished flooring with plastic tarp to avoid getting any of the insulation on it. It's difficult to get out. It's best to apply spray insulation when the temperature is between 60 and 80 degrees F.

Apply the spray from about two feet away. Attach your sprayer to the canister or bucket of insulation and start spraying, as if you were washing a window or car. Don't get too close, but stand a few feet back and spray as evenly as you can, back and forth across the area to be insulated. If you're spraying inside a wall, count to three, then stop and examine your progress to make sure that you aren't over-filling the wall. Insulation needs to be kept in a layer no deeper than an inch. Over-applying foam insulation can stress the walls and can also clump up and fall off the surface. If you miss, or get insulation somewhere you don't want it, don't panic. Stop and allow the insulation to dry and scrape it off the surface with a putty knife later. Trying to smear it now will make it worse. If you need to add multiple layers, because you're spraying an external wall or want extra sound-proofing, wait until the first layer has dried before going back over it as you did before. This will build up the R-Value of the insulation accordingly, and should stick perfectly well.

Fire-sheath spray-insulated walls. Spray foam is not a finished surface and will ignite quickly in the event of a fire. After applying, it's common to drywall over the insulated area to finish the job.

Comments

0 comment