views

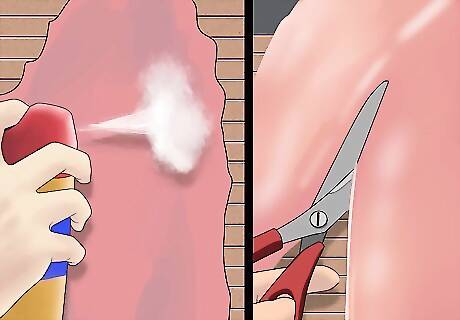

Prepping the Hide

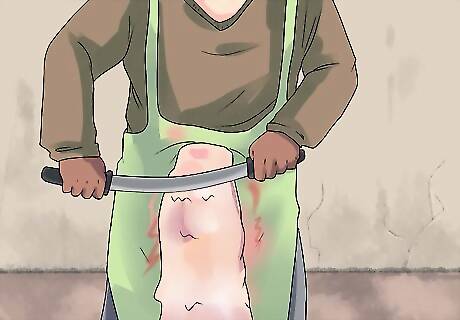

Remove the skin from the flesh of an animal. Skin the animal by setting it on it's back, on an incline when possible. Use a good hunting knife for skinning, and a gut hook knife to gut the animal. Begin by removing the sex organs. Slice the animal from the tail to the throat. Peel back the skin with your fingers or a knife. Split the sternum, spread the rib cage and remove the organs. Flip the animal over and finish removing the hide.

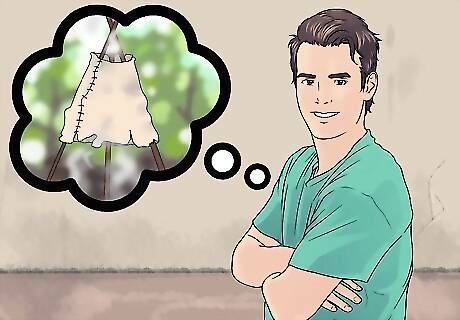

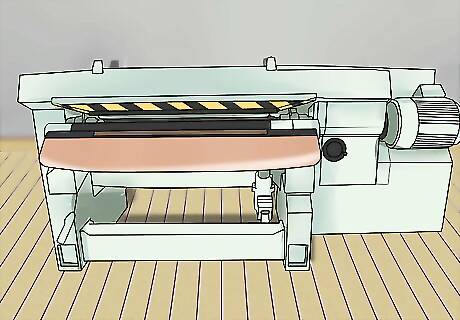

Pull the flesh off the hide. Manufacturers use a mechanical fleshing machine to remove the flesh from the inside of the skin. Running the inside of the skin over the steel roller of the machine will eliminate any excess flesh. If you don't have access to a fleshing machine, you can purchase fleshing tools from a hunting store or taxidermy supply store. Drape the flesh over a large horizontal beam. Stand at the end of the beam and pin a small section of the hide to the end of the beam using your body weight. If you don't have a beam to use or don't want to construct one, you can simply spread the hide out on a tarp on the ground. Place a large basin or bucket below your work area to catch the excess tissue and fats as they are scraped away. Scrap away all the subcutaneous materials with your fleshing tools. Remove the veins and membrane. Rotate the hide and work until the surface is complete. Do not leave the hide if you need to take a break as the material can dry out. After the hide has been fleshed, the end result should be a white, smooth surface.

Salt the skin. Apply a generous layer of salt to the skin, or create a brine and soak the skin. This will act as a preservative to keep the hide from decomposing. Fresh skins need to be salted or frozen within the first few hours, otherwise they may be destroyed. Fold the hide in half so the flesh sides are together. Leave for 24 hours. Scrape away any remaining salt and repeat. To create a brine, add one pound (.45kg) of salt per one gallon (3.8L) of water to create a solution. Let the hide soak for 24 hours.

Soak the skin in water. Soaking will help remove any dirt or other materials from the skin. Fill a large 35 gallon (132L) or so container with fresh, cool water. Place the hide in the water for at least a day. The longer you let the hide soak, the easier it may make the hair removal process.

Remove the hair from the skin. This can be done chemically with a solution of calcium oxide (also known as slaked lime, whitewash, or calcium hydroxide) bath. You can also use the same tools for dehairing that were used for fleshing. Remove all the hair and the epidermis, then hang the skin to dry.

Give the skin a final lime bath. Add one teaspoon (5mL) of calcium hydroxide per gallon (3.8L) of water to create limewater. This bath is known as bating and will remove any inter-fiber substances and unnecessary proteins. It will also help to soften the skin and loosen any remaining hairs. Remove the skin from the lime bath and rinse it thoroughly until clean.

Tanning The Leather

Decide on a tanning process. This can be a one to four day process, depending on which method you choose. Perform a vegetable tannage. A vegetable tannage uses tannin extract, which occurs naturally in a variety of different tree barks like oak, chestnut, tanoak or hemlock. The tannin extract is mixed with water and placed in a rotating drum along with the animal skin. The rotation of the drum will evenly distribute the extract over the skin. This process takes about three to four days and produces a leather that is flexible and used for furniture or luggage. Perform a mineral tannage. Mineral tannage uses a chemical called chromium sulphate. The chromium sulphate has to sufficiently soak into the animal skin to achieve proper tannage. This process takes around 24 hours to complete and produces a leather that is stretchable and used for garments and handbags. Tan a hide with brains. Brain tanning is a popular home method for tanning hides. They say each animal has enough brains to tan it's own hide. So if you have the brain of the animal use that, or you can buy a brain from your local butcher. Combine with a pint (473mL) of water and blend it until it is smooth. Use a large pot to boil the mixture. Add the boiled brains to a large bucket or drum and add some water to cool it. Keep the water at a four-one ratio to the brain. Add the hide and massage the mixture into the skin thoroughly. Leave at room temperature for up to 24 hours.

Load the leathers into a large drum. You will need a large container to hold all your hides and the tanning agent. Look for a container around 35-40 gallons (132-150L).

Add the tanning agent to the drum. The tannin which you select will displace the water and replace it will collagens from the chemicals or substances. You will need to let the leather soak from several hours to 6 days depending on which tanning method you select and the size and quantity of the hides.

Add any dyes to the container. Dyes are what can be used to give the leather a color other than the natural look. If you are going to dye all of your leather the same color, you can add the dye during the tanning process, or you can wait until after the tanning process.

Rinse the leather. The leather will need a thorough rinse after tanning. This will ensure any chemicals and dyes are removed. Use warm water and some mild soaps that contain natural ingredients.

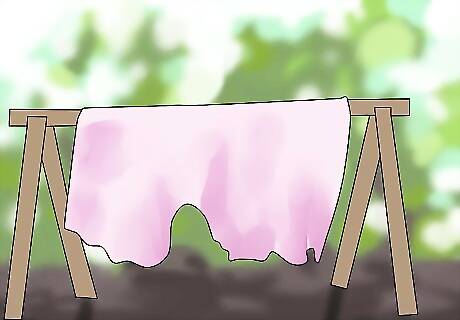

Dry the leather. After the skins have gone through the tannage process, they can be considered leather. Hang the leather out to dry. Hang the leather over rods in a cool, semi-moist area. You can use a fan to help speed up the drying process, but leather should dry slowly so be patient. If the leather is not drying evenly, use some damp rags to remoisten the areas that are drying faster.

Finishing the Leather

Soften the leather. A machine called a staker can soften the leather by stretching it and lubricating it with natural oils. This process ensures the leather stays pliable. You can also hang the hide up from your ceiling and stretch the hide as much as you can in all different directions. You can use ropes and hooks to keep the hide taut.

Apply a leather softening oil. Once a hide is about 80% dry, apply the oil to the surface on the skin side. Coat the entire surface evenly. Repeat several times through the drying process.

Smoke the hide. The hide is soft and pliable, but depending on your purpose you may want to smoke the hide to force the tannin into the fibers. Stitch the hide to form a bag and suspend the opening above a small smoky fire for several hours. Different kinds of wood can even add a natural color to your leather. Aspen or cottonwood can create a golden leather. Try different woods available in your area to see what different colors and looks you can create.

Apply a finish. The leather can be buffed or polished. You might choose to treat the leather with a coat of acrylic or polyurethane to make patent leather. You can also emboss leather to create permanent shapes or designs in the fabric if desired. Finally, cut the leather based on the end user's specifications.

Comments

0 comment