views

Consider your application. While gas chromatography remains the same at the core, different applications require different accessories (columns, injectors and detectors) to run the machine. What you are analyzing? How will you inject your sample into the machine? Which chemical species do you expect to see? These answers will determine which column, detector, injector and carrier gas you will need. You must choose an appropriate calibration gas for your application. This gas will be used to provide the basis to measure the retention time of your gas samples.

Check accessories and turn on the machine. Ensure that the accessories are properly attached to the machine and have no leaks. If this is your first time setting up this machine, contact a professional for help. Once the machine is turned on, it will perform preliminary checks.

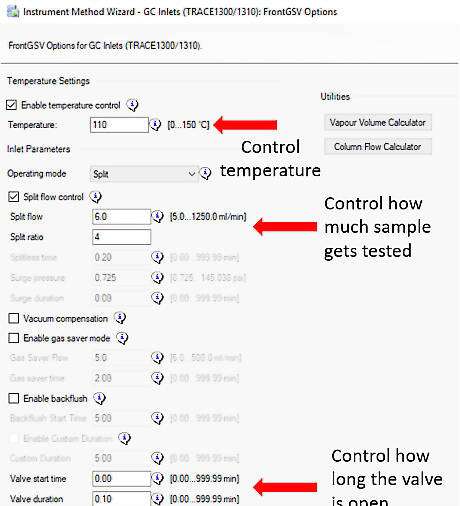

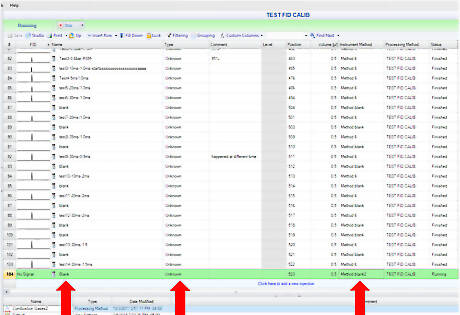

Set up your instrument method in the software. This is a set of commands you create that the chromatograph follows. These commands include settings such as: temperature ramp profile, final temperature, and valve duration. Follow a recommended profile. This is dependent on the application and can be provided by the manufacturer. More experienced users may tweak the settings to decrease the time of the analysis.

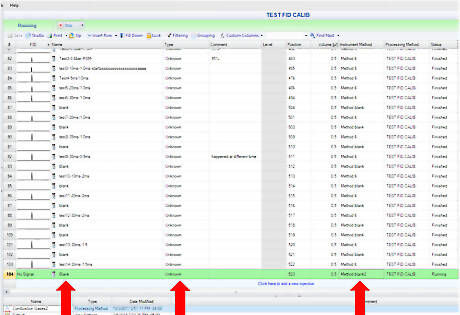

Perform a blank run. A blank run is a way the chromatograph clears itself from residual components left unintentionally from previous runs. This is crucial to ensure that the test sample is not contaminated by residual components! Blank runs do not need a sample injected as they rely on the carrier gas to move the residual components out of the machine. Blank runs can be created by the user using an instrument method as explained in the previous step. You might need to perform a couple of blank runs to clean the system completely. There should be no remaining components detected on the chromatogram.

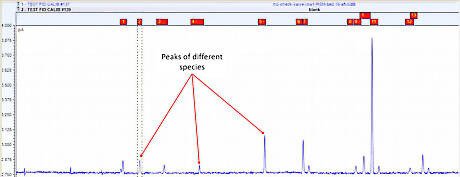

Inject a sample of the calibration gas into the machine. You will need to run the same case multiple times in order to account for errors that change the retention times and differences in peak height. You will need multiple calibration gas samples with different concentrations of the desired components to form a complete calibration curve. For example, if you are testing for traces of methane in a gas sample, find at least two calibration gases with differing amounts of methane in them. Don't forget to run blank runs between your calibration cases! This will increase the accuracy of the calibration.

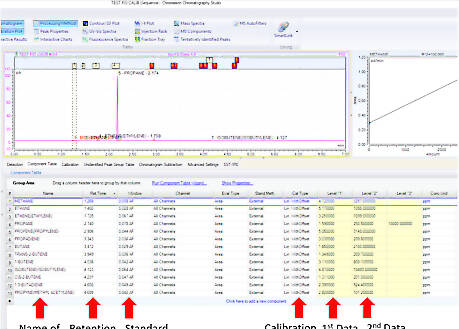

Enter calibration concentrations using the available software. Once all of your calibration runs are complete, you will need to create a new calibration standard. A calibration standard is a reference used by the software to quantify the amount of components of unknown gas samples. Go through the data and insert the correlating amount for each gas as specified by the calibration gas for the average of your calibration results. This will allow the software to measure the amount of a certain species you have in your sample and interpolate/extrapolate if the quantity of the test species in the sample differs from the calibrated amount.

Perform another blank run after calibration and before operating the chromatograph. Remember, the goal is to avoid contamination that might skew the results produced by the gas chromatograph.

Inject your sample into the machine with the specified instrument method created earlier. The chromatograph should display the concentrations of the species within the sample if calibrated correctly.

Comments

0 comment